Company details for:

Scaglia Indeva Ltd

Coney Green Business Centre,

Clay Cross,

Chesterfield,

Derbyshire,

S45 9JW,

United Kingdom

Quick Links:

Products

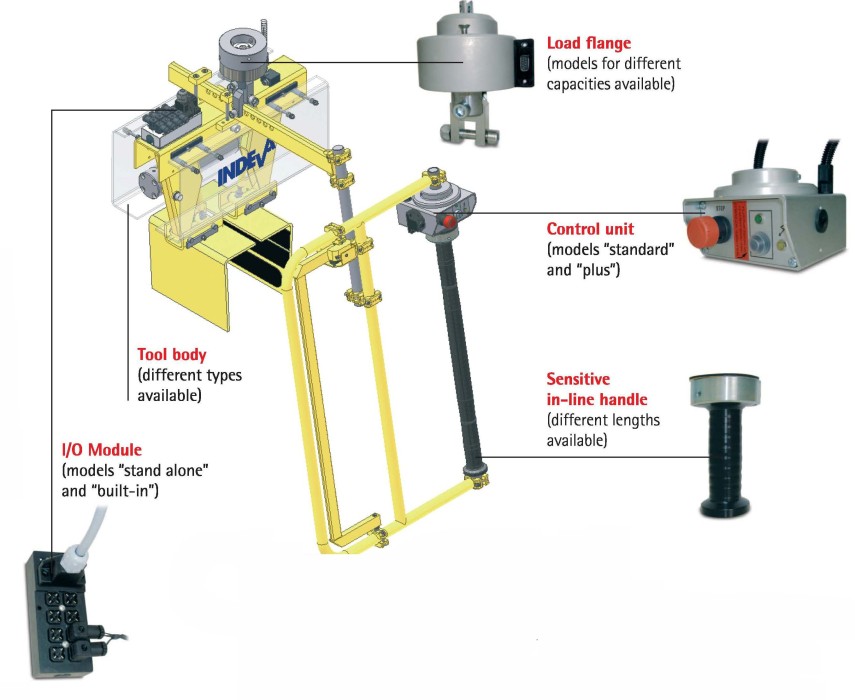

Liftronic® Pro

Models with capacities up to around 300kg

Suitable for bespoke handling solutions involving simple load rotation, vacuum gripping and job specific control. Models with capacities up to around 300kg.

As with all of our industrial manipulators in the Liftronic family, the Liftronic Pro is a key product in our unique, electronically controlled lifting and handling portfolio of solutions. This product represents the evolution of traditional industrial manipulators and is at the forefront of its field.

The Liftronic Pro is suitable for custom handling solutions involving load rotation, vacuum gripping and/or special handling controls, and offers advanced health and safety features which far exceed its traditional predecessors.

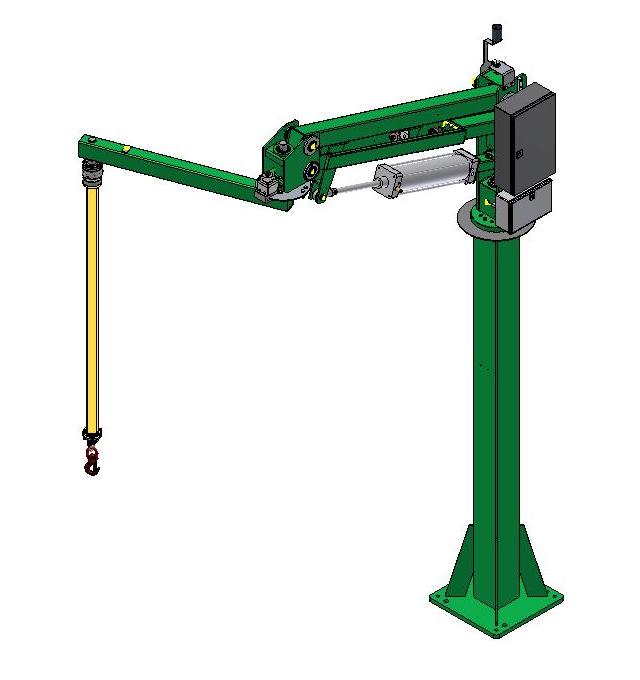

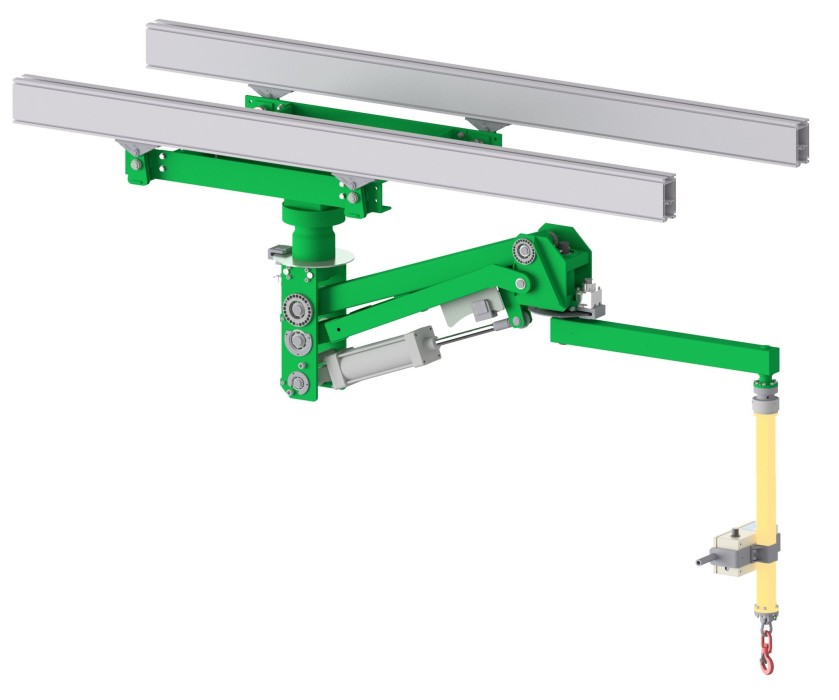

The Liftronic Pro is designed to lift loads ranging from 80kg to around 300kg in capacity, including the weight of the bespoke end-tool. It can be applied to different supports such as a column with orbit arm, ceiling, overhead rail and bridge crane system, examples of which can be seen below.

The Liftronic Pro series of electronic manipulators are zero gravity balancers and represent a new ergonomic solution in materials handling, solving the demand for increased productivity and safety.

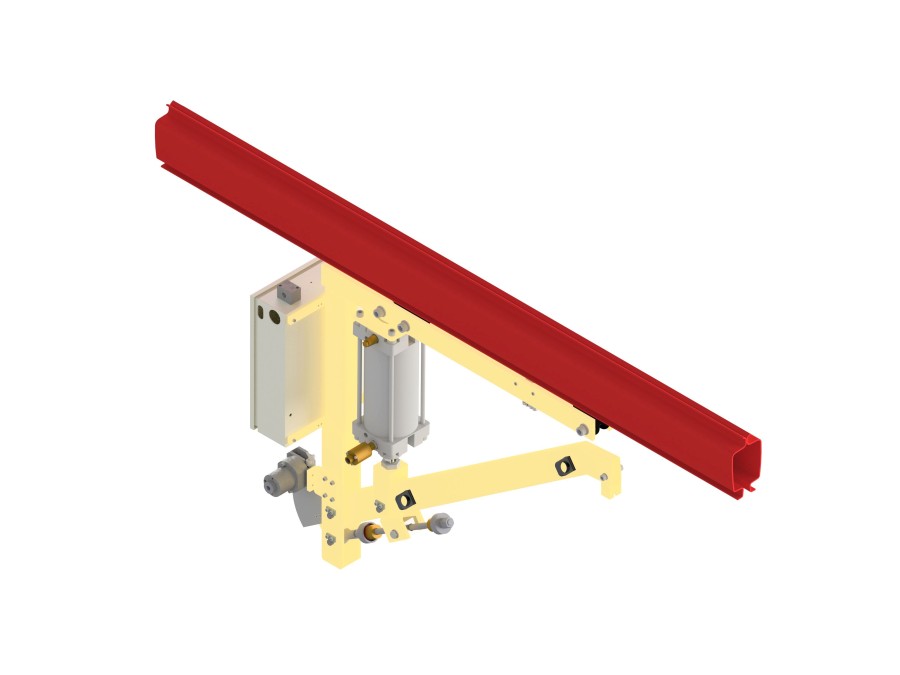

Liftronic® Air − combining the latest electronic and pneumatic technology

Electronic control and pneumatic drive.

The Liftronic Air combines the intelligent electronic control system of the Liftronic Series with a rigid parallelogram arm structure typically found in our pneumatic range of industrial manipulators.

The Liftronic Air represents state-of-the-art technology for handling offset loads − combining the innovation of electronic control with the use of air, this manipulator is unrivalled on the market and offers significant cost-saving benefits across the lifetime of the manipulator.

Power is obtained using pneumatic technology, combined with the intelligence of electronic control.

The health and safety features associated with the Liftronic Air are unrivalled in the market − our extensive development of these features means they’re the safest on the market; even in the case of an emergency, such as power failure, the manipulator will not move, jolt or drop the load it’s holding, protecting both the operator and the load.

Liftronic® Easy

Standard gripping tools are attached directly under the touch sensitive handle.

Models with capacities up to around 300kg

The Liftronic Easy is designed for simple applications and non-complex, rapid work cycles. Standard gripping tools are available, with a touch sensitive control handle. As this is such a simple device, it is possible to quickly replace gripping tools to suit different load types with complete ease.

Compared to a hoist, or traditional pneumatic manipulator, the Liftronic Easy allows for quicker load handling movements, more precise load placing, auto-weight sense and balance, greater ease of use and a consistent increase in productivity and efficiency. Ergonomics is also significantly improved for the operators, and more comprehensive health and safety features are provided for the manipulation of delicate loads.

Simple to install and easy to maintain, the Liftronic Easy is a cost-effective lifting and handling solution, trusted by the worlds’ leading manufacturers.

INDEVA® Liftruck − transpallet, lifting truck or order picker mounted with an electronic manipulator.

One operator can carry out a complete work cycle, from collecting pallets, to loading them and transporting the products to their destination. An electronic balancer is present to provide a smooth, quick and precise handling.

The Liftruck has a maximum lifting capacity of 50kg and vertical stroke of 3,000mm. It is controlled using a 24volt electric power controller and can be fitted with a jointed arm, the size of which can be custom made. As well as a gripping tool, it is possible to fit the device with a vacuum gripper.

Like all products in the Liftronic family, the Liftruck is fitted with a range of sophisticated health and safety features and devices.

PN Compatto (PNC)

Compact structure design.

Models with capacities up to 100 kg.

The PN Compatto range consists of innovative pneumatic industrial manipulators with rigid vertical arms, suitable for applications in restricted and low ceiling work areas.

This series comes with an array of available options including a rotating joint on the axis and a system lock for the lift capacity. There is a brake function which works for the up and down movement and additional brakes are available for the rotational axis. These provide instant braking as soon as activated. Available in special paint finishes and as an attachment to an overhead rail system. This manipulator can create huge improvement on any production / assembly line.

In the event of a pressure drop or air loss, all of the Indeva devices retain a grip on their load, reducing the risk of product damage and employee injury. The tool will then slowly descend to the floor before the load can be released.

PN Ergo (PN) − pneumatic manipulator with rigid vertical arm suitable for handling large, offset loads

Models with capacities up to around 300kg.

The PN Ergo (PN) pneumatic industrial manipulators contain rigid vertical arms and are suitable for handling large size loads, especially when loads are offset (not accessible from the top).

Our PN manipulators can be designed according to ATEX regulations as per the EU Directives 94/9 applications in controlled environments with danger of explosion, classified classes 1 and 2 (gas).

The PN Ergo has a lift speed from 15 to 30 m per minute and a low-noise level of less than 70dB. It uses a rotating joint on the articulate axis and a limit switch for the main and intermediate joint axis’.

PN Flex (PNF) − industrial manipulator with flexible rope.

The PN Flex industrial manipulators don’t contain a rigid arm like the others in the pneumatic family, but instead has a flexible rope, making it ideal for handling loads which have their centre of gravity on the Z axis. These manipulators allow flexible load picking and release movements.

PN Flex lifting equipment is suitable for loads up to 80kg and has a maximum lift speed of 45 m/Min. Like all of Indeva’s pneumatic manipulators, the PN Flex has a low noise level (less than 70 dB) and can be designed to meet ATEX regulations.

PN Zip (PNZ) − light and compact pneumatic industrial manipulators.

Models with capacities up to 80 kg.

The PN Zip industrial manipulators are light and compact, making them idea for applications with a short vertical excursion and quick work cycles.

Able to lift up to 80kg, this versatile pneumatic manipulator features our innovative health and safety features, making them renowned for improving operator wellbeing and reducing product damage.

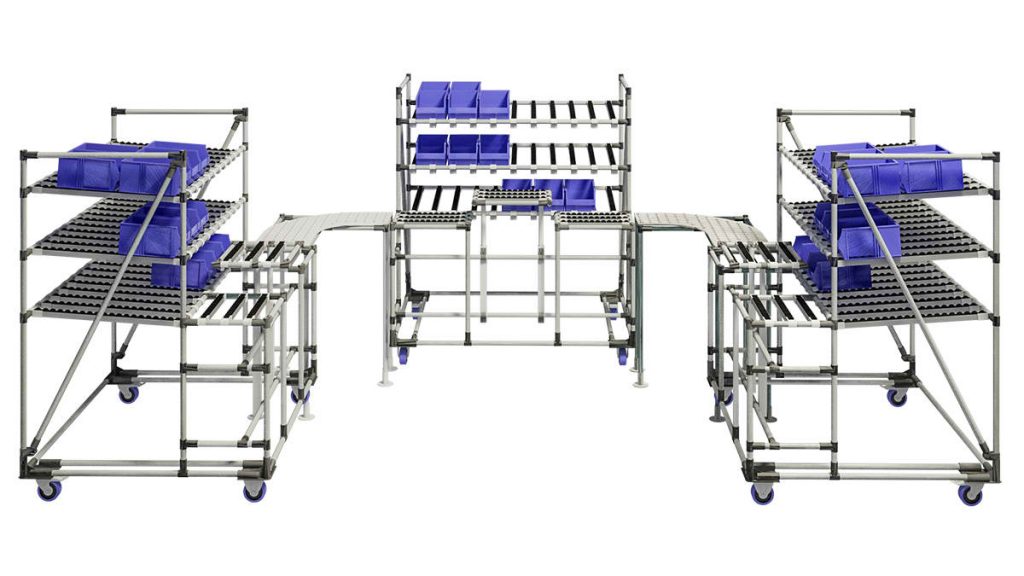

Supermarket Flexible Line Side Stock

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

Flow Ranks

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

Ergonomic Workstations for Greater Productivity

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

Train Set − Flexible Transportation

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

KIT TROLLEYS

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

Special Trolleys

Only limited by imagination

Flexible

Easily modified without special tools or knowledge

Modular

Integrates seamlessly with other LEANSYSTEM® items

Mobile

Wheels available for ease of movement

ESD Compatible

Manufactured with ESD certified components

Design

Choice of colours including black anodised aluminium

Pallet Racketing Shelves

Other Equipment

Welded structures

Pallet trolleys

Sliders

Motor driven trolley

About us

The materials handling equipment provides increased productivity, safety and ergonomics and its installed auto-balancing system makes it easier to lift, rotate, move and precisely position loads up to 250 kg. As well as ease, Indeva products manipulate objects with precision and speed.

With a team of technical, electrical and mechanical engineers on hand the versatile manipulators can be tailor made to suit the needs of the customer.

Products

-

Liftronic (electronic zero gravity balancers)

-

Liftronic Easy

-

PN Ergo

- Lift truck (complete reel handling workstation)