Company details for:

Sonics & Materials (UK) Ltd

Unit 4-5 Sutton Court,

Bath Street,

Market Harborough,

Leicestershire,

LE16 9EQ,

United Kingdom

Quick Links:

Products

ElectroPress™ Plastics Assembly Systems

40 kHz available in 400 & 800 watts

Process data collection for statistical analysis

Programmable digital force, velocity and distance

2 weld velocities for precise melt-down control

Tooling

15 kHz Ultrasonic Assembly System Machines

Special machines

3500 & 4500 watts

Time, energy and distance welding modes

Tooling

20 kHz Ultrasonic Assembly System Machines

Special machines

1200, 1700, 2200 & 3500 watts

Time, energy and distance welding modes

Tooling

40 kHz Ultrasonic Assembly System Machine

Special machines

400 & 800 watts

Time, energy and distance welding modes

Tooling

Ultrasonic Hand Welders for Plastics Assembly

500 watts

Time and energy control

Accessories & tooling

High power hand welders also available up to 3500 watts.

Ultrasonic Tooling

Purpose designed to suit the application

Ultrasonic OEM Kits & Components

Converters, booster, tooling

Generators, switching cards & cables.

Ultrasonic Spot Welding Systems

Ultrasonic Wire Splicing Systems

Ultrasonic Seam Welders

SmartControl Power Supply

Ultrasonic Battery Pack Welder

Ultrasonic Food Cutting Machines

frozen cakes and pies

frozen fish

snack and health bars

fresh/frozen prepared meats

dough or baked cookies

soft and hard cheeses

fresh/frozen vegetables

sweets and confections

ice cream bars

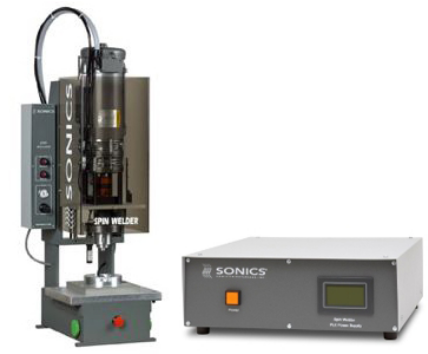

Spin Welders

Spin power head on dual columns

Fixed vertical opening with 10” space

Multi-horsepower electric motor drive

Dynamic braking

Model 1020 Spin Welder

Spin power head on dual columns

Adjustable vertical opening from

10” − 20”

Multi-horsepower electric motor drive

Positive stop adjustment

Dynamic braking

Power Supply

Sonics’ spin welders are powered by a PLC logic-controlled power supply that controls the system's single and two-stage cycle modes, time-based weld settings and rpm adjustments.

Vibration & Hot Plate Equipment

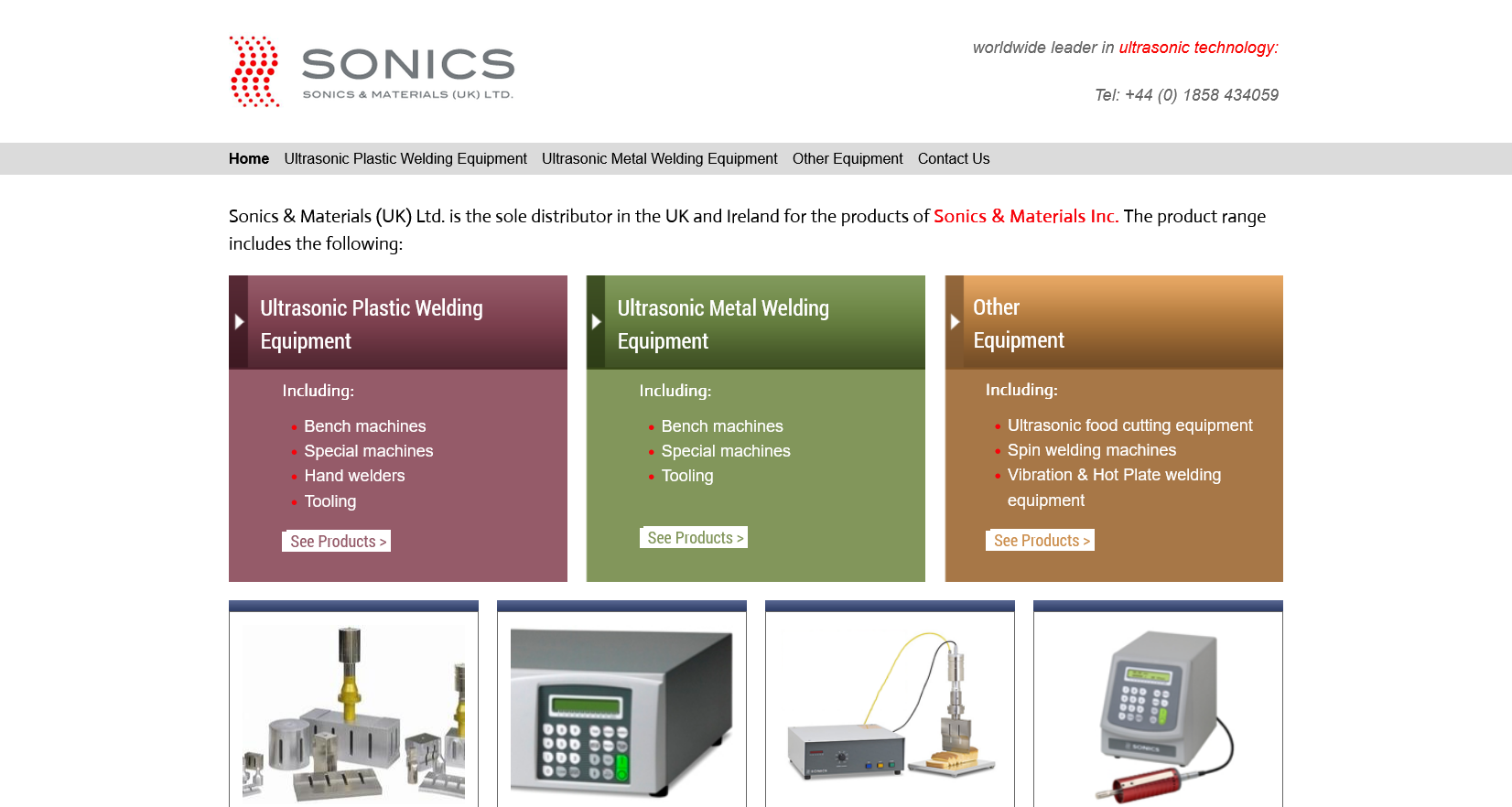

About us

Pioneering advancements in both research and applied technology, Sonics is committed to delivering top-notch products and practical manufacturing solutions. This commitment is reinforced by extensive technical support and expertise in various applications.

Established in August 2004, Sonics & Materials (UK) Ltd. originated by acquiring the plastic welding business from Kerry Ultrasonic. Kerry Ultrasonics, founded in 1954, had been a leading manufacturer of plastic welding and ultrasonic cleaning equipment. The acquisition occurred as Guyson International Ltd. purchased Kerry Ultrasonics in early 2004, with a primary focus on acquiring ultrasonic cleaning capabilities. Consequently, the plastic welding business was divested to Sonics and Materials UK Ltd.

Our Products Include:

Ultrasonic Plastic Welding Equipment

Ultrasonic plastic welding equipment represents cutting-edge technology in the field of joining thermoplastic materials. Utilising high-frequency ultrasonic vibrations, this equipment creates a strong and precise bond between plastic components without the need for adhesives or additional materials. The process involves applying ultrasonic energy to the plastic parts, causing localised melting and subsequent fusion as the materials cool.

Including:

- Bench Machines

- Special Machines

- Hand Welders

- Tooling

This technique offers distinct advantages, including minimal heat-affected zones, precise control over the welding process, and the ability to join dissimilar metals. Ultrasonic metal welding finds applications in various industries, from automotive and aerospace to electronics, providing manufacturers with a reliable and efficient method for producing strong, high-quality metal connections without the need for additional materials or filler metals.

Including:

- Spot Welders

- Wire Splicers

- Seam Welders

- Battery Pack Welders

Including:

- Ultrasonic Food Cutting Equipment

- Spin Welding Machines

- Vibration & Hot Plate Welding Equipment

Benefiting from the technical expertise and experience of Sonics & Materials Inc., and possessing nearly three decades of experience in working with ultrasonic plastic welding equipment, Sonics and Materials (UK) Ltd. is well-equipped to support your plastic welding applications.

Images