Tascomp Ltd specialises in developing Prodigy HMI SCADA software for industrial automation, offering robust solutions for monitoring and control.

Prodigy powers several specialised systems, including PlantRun, which integrates hardware and software to help manufacturers improve operations by monitoring production at the asset level. Additionally, PAMS provides centralised alarm management for airfield ground systems.

Other key solutions include Prodigy-ET, designed for engineering test automation and data acquisition, and OEM SCADA, offering customised HMI software development services tailored to specific industry needs.

Our Solutions Include:

Prodigy - HMI SCADA Industrial Automation Software

Prodigy HMI SCADA industrial automation software, developed and fully supported in the UK, has been successfully utilised across a wide variety of industries and applications worldwide.

Machine Downtime, Machine Utilisation and Downtime Systems

PlantRun OEE, machine downtime, and manufacturing information systems provide manufacturers with precise real-time production performance data, enabling them to optimise efficiency, boost output, and increase profits.

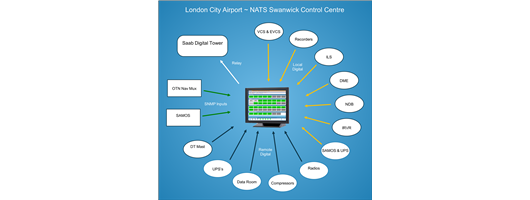

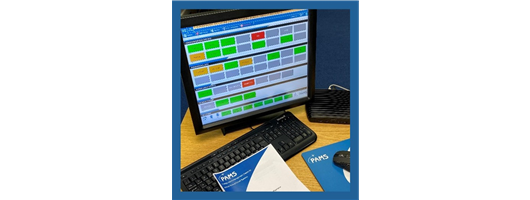

PAMS - Alarm Management for Airport Ground Based Systems

Advanced systems for monitoring airfield ground-based services, covering Air Traffic Control (ATC), Communications, Navigation and Surveillance (CNS), UPS, and meteorological equipment.

Test Automation Software - Prodigy-ET

Prodigy-ET is a comprehensive industrial test automation and data acquisition software suite trusted by leading manufacturers for automated product testing.

OEM SCADA Software and Custom HMI Design and Development

If you need software for new product lines, to update outdated systems, or to enter new markets but lack the time or resources to develop it from the ground up, our OEM SCADA-HMI software provides the perfect solution.

We are proud of the high-quality support we offer for our products.

Depending on the product, our software and systems are available through multiple channels, including a network of resellers, distributors, systems integrators, and direct sales to end users.

-

-

-

-

-

-

-

-

-

-

-

-

Prodigy - HMI SCADA Industrial Automation Software

Machine Downtime, Machine Utilisation & Downtime Systems

PAMS - Alarm Management for Airport Ground Based Systems

Test Automation Software - Prodigy-ET

OEM SCADA Software

Support

End User Support

Training

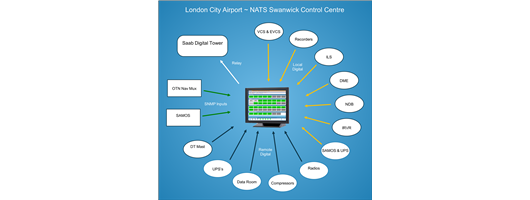

Control Centre Infrastructure

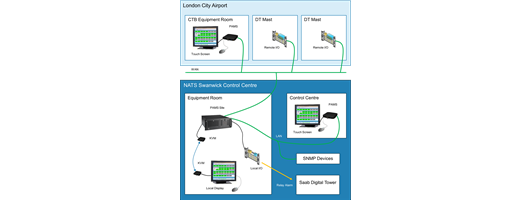

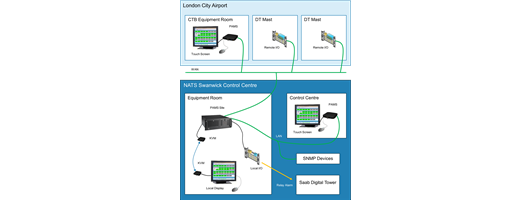

London City Airport Infrastructure Diagram

London City Remote Tower

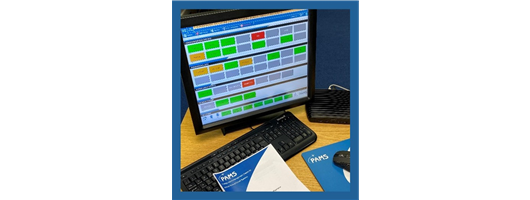

PAMS Alarm Screen

Previous

Next

approvedbusiness.co.ukTascomp Ltd Tel: +44 1642 370666

approvedbusiness.co.ukTascomp Ltd Tel: +44 1642 370666