Company details for:

Trantec Solids Handling Ltd

Four Lane Ends Road,

Stacksteads,

Bacup,

Lancashire,

OL13 0TB,

United Kingdom

Quick Links:

Products / Services

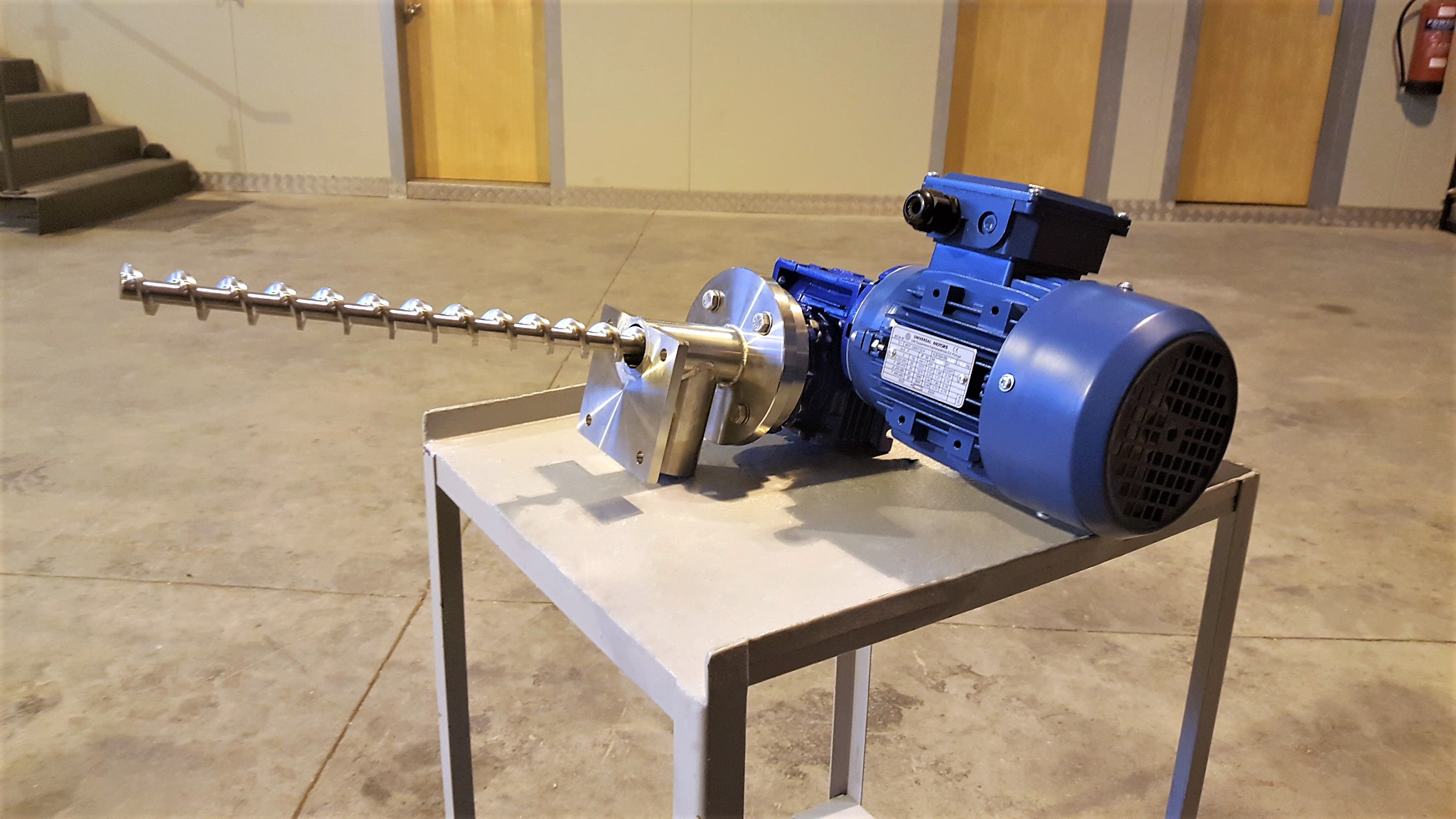

Gravimetric screw feeder

The main purpose of a Gravimetric screw feeder system is to discharge process material a controlled weight-based rate and must also meet three main requirements.

1. Material Handling

2. Weighing

3. Control

Volumetric screw feeder

Volumetric feeders are used in a lot of industries worldwide. These range from Chemicals, Food, Plastics and Pharmaceutical

Volumetric feeders are known or metering fine powders, chips, flakes, granules and pellets.

FIBC Bulk bag discharger

Powder sampler

The sampler is configured for volumetric feeding and can be programmed to manually or automatically take samples in continuous operation or in batches to suit the customer’s needs.

Our powder samplers boasting a low power consumption and simplistic design, Trantec powder samplers require minimal maintenance, alongside providing a cost-effective solution.

Sack tip station

Dry bulk solids are kept fully contained with the addition of dust curtain taking away any risk of cross-contamination. Available upgrades include:

> Keg-tip mechanism powdered by a Belimo actuator

> Mobile sack tip on wheels.

> Door with safety interlock and switch.

> Metal detectable silicone gaskets.

Flexible screw conveyors

Construction:

Trantec’s Flexible Screw Conveyors are constructed in mild steel, 304, or 316 stainless steel with a variety of polish finishes to choose from. These include welds as laid, standard, crevice-free, and mirror (0.2Ra). These materials include construction of any inlets, outlets, hopper, lids, agitators, connection flanges, and drive shafts.

Mild steel (or low-carbon steel): A composition of iron, carbon, and manganese, it is a low-cost construction material. Known for its ease in shaping, making manufacturing this steel alloy cost-effective and easy to manipulate. Not suitable for food contact or pharmaceutical processes.

304 stainless steel: An alloy composition containing 18% chromium and 8% nickel, 304 stainless steel is the most common construction material around the world due to its resistance to acidic and caustic solutions, combined with reduced risk of intergranular corrosion and high ease of fabrication.

316 stainless steel: Greater resistance than 304 stainless steel. Easier fabrication, welding, and cleaning properties. Increased resistance to sodium chloride (NaCl) based substances. Typically used for the construction of food and pharmaceutical solutions.

Flexible conveyor spare parts

Our parts are manufactured to the highest specifications and to the same, exacting standards as the original equipment manufacturer (OEM), providing guaranteed interchangeability, at a sensible price. We have seen a large increase in spares sales, with newer and more diverse applications relying on our services regularly. Transferring to Trantec’s Flexible Screw Conveyor spares has made a difference to many small businesses, universities, multinational companies and household brands, helping them save money and further improve their processes, omitting the need to return to their original OEM.

Trantec’s Flexible Screw Conveyor parts include:

Conveyor Spiral - made from stainless or carbon steel, available in round, flat or square section. We can provide custom-made spiral to your exact requirements, or you can buy many standard sizes ex-stock.

Conveyor Tube - UHMWPE (Ultra High Molecular Weight Polyethylene) Tube is extruded from FDA and EC approved food contact material and is available in a range of sizes with many sizes ex-stock.

Fabricated/Machined Parts - our in-house fabrication and CNC machining facilities enables us to offer better pricing. We manufacture specialist stainless steel parts in a range of finishes including mirror finish.

Auxiliary Components - Electrical Controls, Flexible Connectors, Dust Socks and custom manufactured parts are also available. Please contact us for a quotation.

Micro screw feeder

About us

Trantec Solids Handling Ltd is a leading supplier of powder handling equipment to the world-wide solids and bulk handling industry, providing solutions aimed at metering, dosing, weighing, filling and conveying. Spanning over two decades, our continual dedication to research and development has enabled us to produce innovative solutions, setting the highest standards of equipment manufacture.

Our products are designed for use in industries such as food, pharmaceutical, chemical, environmental and plastics. Our commitment to quality and reliability means our customers receive a product they know they can rely on time and time again.

Our aim is to meet each individual customer’s needs. At our modern production facility in Clayton-le- Moors in Lancashire, our experienced design engineers, together with our enhanced manufacturing techniques produce superior products that can be adapted for use in any application. Our product range includes:

- Volumetric Screw Feeders

- Gravimetric Screw Feeders

- Flexible Screw Conveyors

- Specialist Auger Screw Manufacture

- Custom-made Spiral

- Conveyor Spares

- Bulk Bag Dischargers

- Hoppers

- Sack Tip Stations

- Powder Samplers

In-keeping with Trantec’s policy of continual development, we now offer custom-made auger manufacture. Often replacement parts need to come from the original equipment manufacturer (OEM) who charges a premium for such a bespoke component. Our investment in the latest Computer Aided Design (CAD) and Computer Aided Manufacture (CAM), together with our experienced design engineers means reproducibility can be easily achieved and fractions of a millimetre in accuracy can be maintained across batches. This, along with minimal human intervention during production, means we can produce replacement auger screws at a fraction of the cost.

For more information, please contact us.

Sponsored Links

Articles / Press Releases

Reviews

Trade Associations