Company details for:

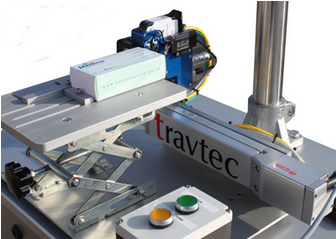

Travtec Group

Unit 17,

Leigh Business Park,

Meadowcroft Way,

Leigh,

Greater Manchester,

WN7 3XZ,

United Kingdom

Quick Links:

Products

Conveyor Accessories

Pharma Products

Our machines are used all over the world and our customers come back to us time and again. We have a range of standard machines offering you the ultimate answer to your problem.

Special Products

From concept to operation, our project management team will work with customers technical and production personnel, to ensure the final product is within specification and timescales.

We operate as a full partnership with our customers, ensuring total communication regarding progress of the project, enabling mid-term modifications to be achieved if necessary, with minimum disruption.

Our facilities include: Technical Management with Concept Development and Mechanical and Electrical Design using the latest CAD facilities. A Project Management team to define customers specifications, and ensure delivery deadlines. CNC Manufacturing capabilities for perfect repeatability of components. Test Facilities for in-house pre-delivery trialling.

Vision Products

Diverter MK 3

The Diverter 3 is designed to mount to existing conveying lines for coding on the base of containers with a continuous inkjet printer or laser. Used where it is inconvenient to create a gap in the line, it is easily attached to most conveyors up to 150mm wide.

Adjustment between container sizes takes only seconds, and the twin side-belt synchronised drives ensure positive container control and guidance. Manufactured mainly in stainless steel, the Diverter is suitable for most environments.

Paratran MK 4

The Paratan 4 is the latest version of our parallel transfer unit, which is designed to mount between conveying lines for basecoding with a continous ink jet printer or laser. It can also be used for inspection with a vision system or barcode scanner.

Used to transport bottles, jars and cans end to end between conveyors. Adjusting between container sizes takes only seconds with a handwind inciroerating a digital indicator for accurate repeatability. The twin side-belt synchronised drives ensure positive container control and guidance at all times.

The unit comes with an adjustable floor stand in stainless steel, and is suitable for most environments.

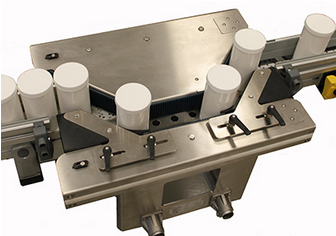

Cap Press

Caps can be manually, or machine placed whilst the container is travelling along a conveyor, replacing hand pressing of closures, eliminating wrist strain and Injury.

Adjustment between container sizes takes only seconds with an integrated handwind and angular adjustment compensating for different container heights.

The variable speed drive is easily synchronised with existing conveyors, and the belt drive ensures positive control and guidance, gently pressing the cap without shock force.

The innovative design is easily attached to most conveyors within 1 hour

Caplicator

Automatic application of snap-on caps for tubs, jars & cans

Caps can be manually, or machine placed in the chute whilst the container is travelling along a conveyor replacing hand pressing of Can be supplied with a bowl/rotary feeder for fully automatic operation.

The variable speed twin-belt drives are easily synchronised with existing conveyors ensuring positive control and guidance, gently pressing the cap without shock force.

The innovative design is easily attached to most conveyors with minimum disruption.

Tiny Tampino

The Travtec TinyTampino desktop unit is designed as an off-line system for semi-automatically applying permanent tamper-evident labels to the closure of cartons.

It is quick, easy and safe to operate, with the active movement being totally under operator control.

Minimum capital outlay. High quality applicator for consistent label placement.

Maintenance-free design with robust construction.

Labelino X-1

The Labelino X-1 tabletop labeller is designed as an off or on-line system for automatically applying self-adhesive labels to round containers such as bottles, jars & cans.

It is quick, easy and safe to operate, automatically applying wrap-round labels accurately and efficiently.

Minimum capital outlay. High quality applicator/conveyor for consistent label placement.

Maintenance-free design with robust construction. Optional floor stand with castors.

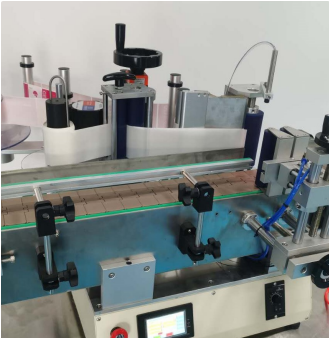

Labelino X-2

The Labelino X-2 tabletop labeller is designed as an off or on-line system for automatically applying self-adhesive labels to flat products such as boxes, cartons & pouches.

It is quick, easy and safe to operate, automatically applying labels accurately and efficiently.to top surface of product.

Minimum capital outlay. High quality applicator/conveyor for consistent label placement.

Maintenance-free design with robust construction. Optional floor stand with castors.

Labelino X-3

The Labelino X-3 tabletop labeller is designed as an off or on-line system for automatically applying self-adhesive labels to the front & back of round containers such as bottles, jars & cans.

It is quick, easy and safe to operate, automatically applying wrap-round labels accurately and efficiently to front & back of products such as wine & beer bottles.

Minimum capital outlay. High quality applicator/conveyor for consistent label placement.

TR-1000 Casefeeder

The TR-1000 Casefeeder is designed to feed flat, unerected corrugated cases for coding with inkjet, labelling, or print & apply. The case is presented to the inkjet printer or labeller in a vertical orientation, allowing both sides (4 faces) to be accessed in one pass.

The Casefeeder can be supplied either as a turnkey system, or for integration with existing equipment to maximise cost benefits, and minimise downtime. Changeovers between prod-uct runs can be completed in less than 5 minutes, and the Auto-Stak outfeed unit presents the finished cases neatly stacked for easy removal by the operator .

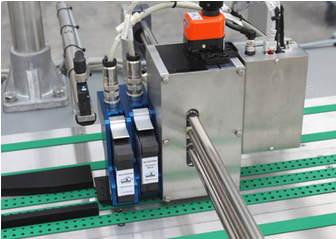

Pharmacarton

The turnkey system combines a precision multi-belt conveyor with a synchronised top hold down belt and can be integrated with an inkjet printer, and an OCR/OCV optical character verification system. A reject station with integrated reject confirmation compliments the total design.

This fully integrated module provides all manufacturers with an easy to operate, flexible system to meet a variety of coding requirements. The station is easily integrated into existing packaging lines using minimum space, and is adjustable to suite a range of carton sizes.

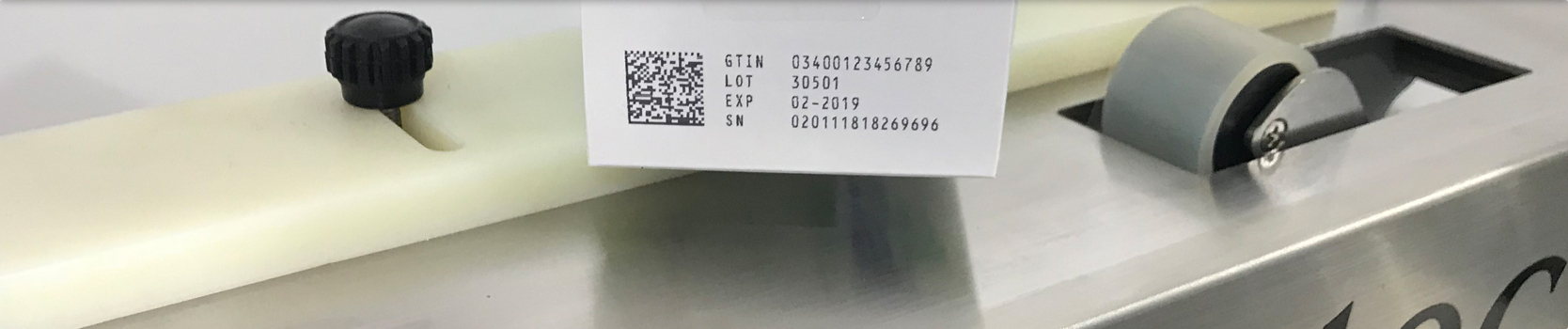

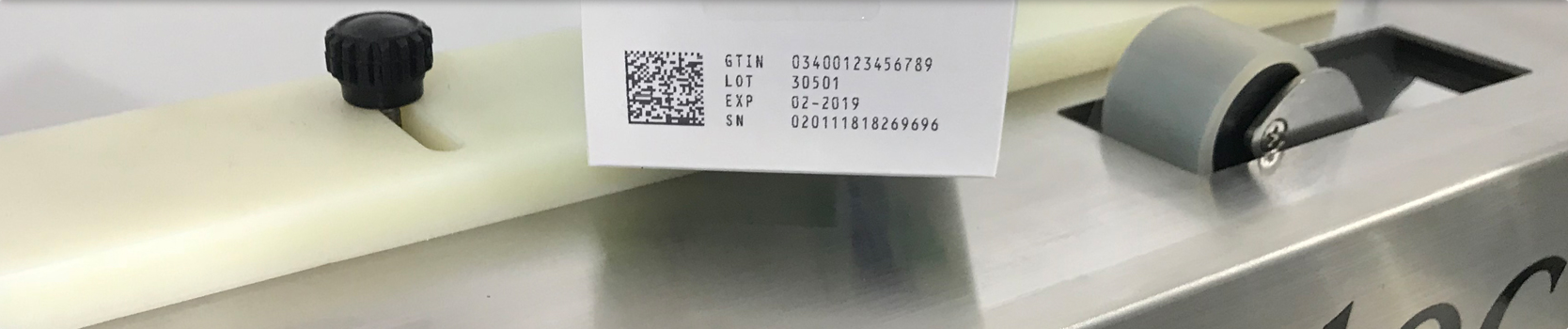

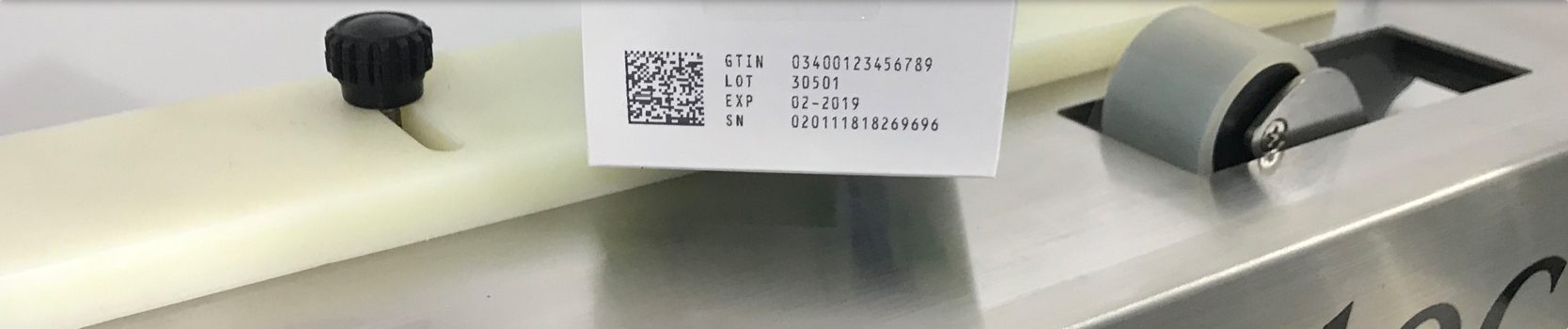

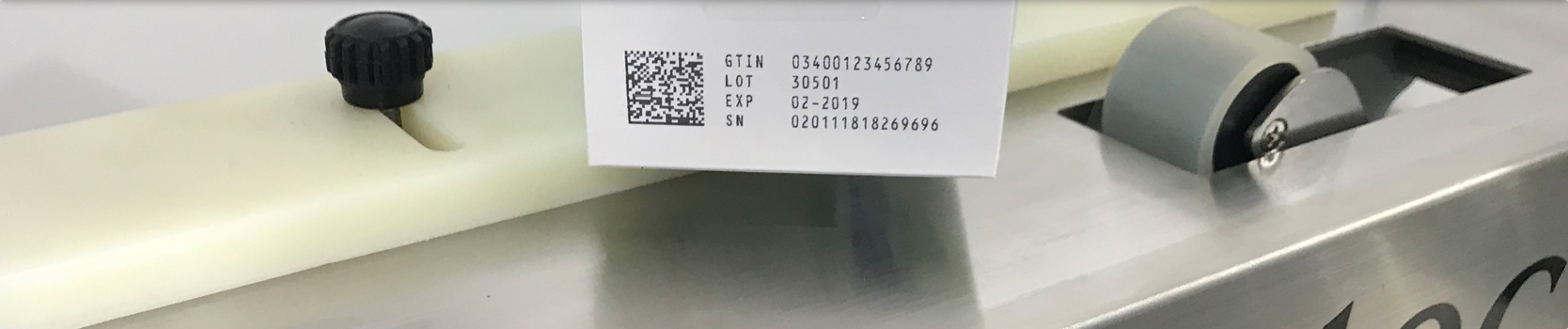

Travtec TR-860

The TR-860 Versa-Feeder is designed to feed flat cartons, folded leaflets, single labels and paper sheets for coding with inkjet or laser, labelling, or print & apply. An OCR/OCV vision system positioned directly after the printhead, confirms & collects the coded data for traceability purposes. A fail to safety reject unit removes incorrectly, or unprinted cartons, and an optional Shingling Conveyor ensures a continual feed for maximum production efficiency.

The machine is ideal as an off-line Serialisation System reducing complexity where cost are a major factor against on-line systems. It is designed to accept most types of high resolution printers and suitable vision systems

Travino

Label printing option for serialising self adhesive labels for hand application to cartons, bottles etc. Minimum capital outlay with rapid changeovers from vertical to horizontal printing. Wide range of carton sizes accepted.

Fail-safe audio-visual indication to operator of unreadable data with positive reset required to commence batch printing. Supplied on stainless steel trolley with castors for portability.

Tiny Labelino

The Tiny Labelino desktop unit is designed as an off-line system for semi-automatically applying self-adhesive labels, vignettes & stickers to packaging items.

It is quick, easy and safe to operate, with the active movement being totally under operator control. Minimum capital outlay. High quality applicator for consistent label placement. Maintenance-free design with robust construction.

Lixis PVS

LIXIS PVS is the inspection unit used for serialization (variable data) and Track & Trace projects.

Lixis Blister Control

The inspection of production with our machine vision technology guarantees that 100% of the items are accurately packed, thus eliminating errors and reducing costs related to human control.

Lixis Pinhole Detection

Lixis Code-Pro

Following LIXIS high quality standards, CodePro equipments meets every specific need in pharmaceutical industry.

About us

We pride ourselves on our ability to work successfully in a diverse range of industries such as pharmaceuticals, toiletries, cosmetics and food. Our wide range of products include Diverter 4, Paratran 4, Cap Press, Tiny Tampino, , Travino, and many more. We specialise in engineering packaging services for clients across the UK & Europe and continue to expand our services on a global scale. We encourage anyone who wishes to increase their production efficiency to get in touch with our sales team right away to discuss any upcoming projects.