Experts in Mild Steel Fabrication

23 March 2023

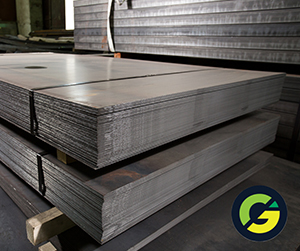

Mild Steel is the most common metals used for components fabricated at Grenville. Mild Steel is a ferrous metal made from iron and carbon and has exceptional tensile and high-impact strength.

The higher melting temperature means that mild Steel is more ductile when heated, making it suitable for forging, cutting, drilling, and welding and easy to fabricate.

The higher melting temperature means that mild Steel is more ductile when heated, making it suitable for forging, cutting, drilling, and welding and easy to fabricate. While every product is unique, most begin life at Grenville as a flat sheet of mild Steel. The metal is laser cut using one of our rapid Bystronic fiber laser machines or, depending on requirements, punched with our CNC Trupunch 3000. Once cut, we form the part into the desired shape using one of our six press brake machines. It can then be assembled and welded by one of our highly skilled welding team.

All components are then subjected to rigorous deburring, grinding and dressing procedure to ensure the highest quality finish.

Mild Steel isn’t rust-proof. We, therefore, offer metal finishing services working to customer specifications, from shot blasting, painting, powder coating, and galvanizing to zinc plating. We carefully select premium suppliers to finish parts to a high standard, including BS EN ISO 1461, ISO 9001 and AS9100 delivering the highest quality finish.

Spanning more than four decades of experience and dedication we produce the highest quality products from mild steel, stainless steel, aluminum to all specifications supported through the latest Enterprise resource planning (ERP) system.

Why chose Grenville? We are committed to providing outstanding quality components and customer service and technical expertise to an ever growing diverse range of customers from concept to delivery.

Other Press Releases By This Company

- 16/12/2024 - 40 Years Strong

- 26/11/2024 - Celebrating 40 Years of Excellence: Grenville Engineering’s Milestone Anniversary

- 15/10/2024 - Reshoring Drives Growth and Innovation

- 07/08/2024 - Grenville Sponsors STEM Project

- 17/07/2024 - Grenville Engineering Invests £60,000 in First CNC Vertical Milling Machine to Enhance In-House Capacity.

- 23/05/2024 - Grenville Engineering: Eight Years of Excellence in Fabrication Solutions at Subcon and Celebrating 40 Years of Innovation

- 25/04/2024 - Maximising Efficiency Training

- 21/03/2024 - New Tube Laser Cutting Machine

- 05/03/2024 - Grenville Engineering's £250k Investment in State-of-the-Art RVD SmartFibre CNC Tube Laser Cutting Machine

- 15/02/2024 - Grenville Engineering Returns to Subcon 2024: A Showcase of 40 Years of Precision and Progress

- 19/01/2024 - 40 Years Strong: Grenville Engineering's Milestone Celebration at Southern Manufacturing Trade Show

- 19/12/2023 - Reflecting on 2023

- 24/10/2023 - Grenville Engineering Enhances Capabilities with Arrival of State-of-the-Art Tube Laser

- 23/10/2023 - Navigating the Waves of Q3 2023 with Positivity and Efficiency

- 14/09/2023 - Empowering the Future of Energy

- 30/08/2023 - How Grenville Drives Waste Reduction in Metal Fabrication

- 14/08/2023 - The Grenville Engineering Family Business Grows!

- 28/07/2023 - Record-Breaking sales delivered!

- 14/07/2023 - Record-Breaking Million-Pound Sales Delivered in June

- 22/06/2023 - Grenville Impressive Return to Subcon

- 22/06/2023 - Impressive return to Subcon

- 16/05/2023 - Subcon June 2023

- 12/04/2023 - Everything you need to know about steel

- 10/02/2023 - National Apprenticeship Week 2023

- 31/01/2023 - New year... New Machine

- 30/11/2022 - Quality assured at Grenville

- 24/10/2022 - Metal Matters - October 2022

- 26/09/2022 - More capabilities and capacity

- 03/08/2022 - Why choose Grenville Engineering & UK manufacturing?

- 11/07/2022 - Spotlight on sheet metal punching

- 10/03/2020 - Bespoke roof ventilation

- 27/11/2018 - Grenville Engineering is a leading sheet metal fabrication company who has always taken pride in its long standing relationships.

- 27/11/2018 - Grenville’s diverse range of customers include companies within the dust filtration industry.

Released By

Grenville Engineering (Stoke-On-Trent) Ltd