23 April 2024 | RH Technical Industries Ltd

Improve the functionality of your product with Flexible Printed Circuits and Conductive Inks.

The world of electronics is constantly shrinking. Our phones are getting thinner, our components lighter, and our devices more versatile.

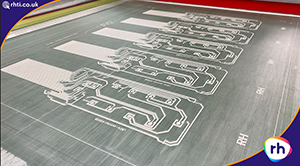

This miniaturisation trend wouldn’t be possible without advancements in flexible printed circuits (FPCs). The term, FPC usually refers to a circuit etched from copper foil laminated onto a polyimide film. The second option is Silver Printed Circuits (SPCs). These use a conductive ink containing silver particles printed on a flexible base film, typically polyester. At RH Technical Industries, we offer both options: printing the SPCs in-house and the FPCs we source from our trusted partners in China.What are Flexible Printed Circuits?

FPCs are essentially thin, flat circuits made of a flexible plastic substrate instead of the rigid fibreglass boards found in traditional PCBs. This flexibility allows for incredible design freedom. Imagine a circuit that can bend, fold, and even twist without compromising performance. This makes them ideal for applications where space is limited or where the circuit board needs to conform to a curved surface.

RH utilises both silver and copper circuits in their membrane keypad and capacitive switch manufacturing. The copper circuits are reserved for the most demanding applications due to its superior conductivity. Silver-printed circuits (SPCs) offer great functionality at a fraction of the cost. They are ideal for conveniently connecting resisters and LED backlighting to a membrane switch design. While silver ink carries lower conductivity than copper, SPCsstill provide excellent flexibility for many applications. The silver ink is printed directly onto the SPC base material, creating a network of conductive pathways for various applications.

Features and Benefits

Here at RH, we utilise both FPCs and SPCs in our customers’ projects. Here are some of the benefits:

Reduced weight and size: Printed circuits are significantly lighter and smaller than traditional PCBs. This makes them ideal for applications in handheld or mobile devices.

Improved functionality: Printed circuits’ flexibility allows for innovative designs that would be impossible with rigid PCBs. Imagine a product with a display on a curved housing or an interface located away from a direct connection to the PCB.

Enhanced durability: Printed circuits can withstand bending, flexing, and even some vibration without breaking. This makes them perfect for harsh environments or applications that require constant movement. (Remember that FPCs are the more robust in construction)

Simplified assembly: Printed circuits can be pre-shaped to conform to the final product, streamlining the assembly process and reducing production costs. This means that insteadof flat rectangular boards, these circuits are manufactured with bends or curves built into them during production.

The Customers Needs

But the benefits extend beyond the technical aspects. Here’s what our customers gain by partnering with RH for their FPC needs:

Faster turnaround times: Because Printed circuits can be manufactured with fewer components and a more straightforward assembly process, we can deliver them to you faster, keeping your projects on track.

Reduced overall costs: The lightweight nature of Printed circuits and the streamlined assembly process contribute to lower overall production costs.

Expert design and engineering: Our team of experienced engineers will work closely with you to design and develop an FPC or SPC solution that meets your specific application requirements.

Reliable, high-quality products: We use only the best materials and employ rigorous quality control measures to ensure your Printed circuits are built to last.

At RH Technical Industries, we believe that FPCs and the conductive inks of SPCs are the future of electronics. Printed circuits might be the perfect idea for you if you’re looking to create lighter, thinner, and more versatile devices with unusual shapes. Contact us today to discuss your printed circuit needs and explore how we can help you push the boundaries of what’s possible.