Company details for:

WDB Ltd

Unit E1, Coombswood Business Park,

East Coombswood Way,

Halesowen,

West Midlands,

B62 8BH,

United Kingdom

Quick Links:

Products / Services

Wilkinson Dynamic Balancing Ltd

Industrial Fan Services Ltd

BR Engineering

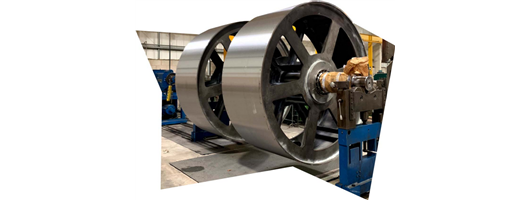

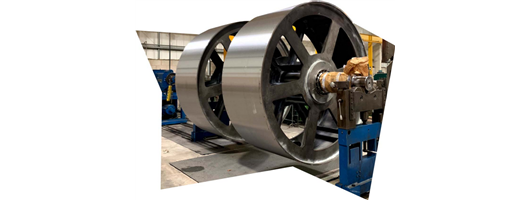

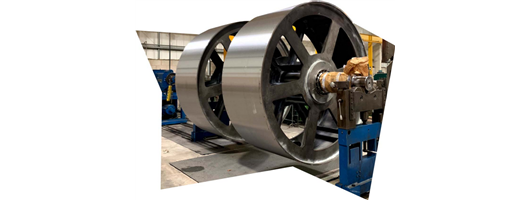

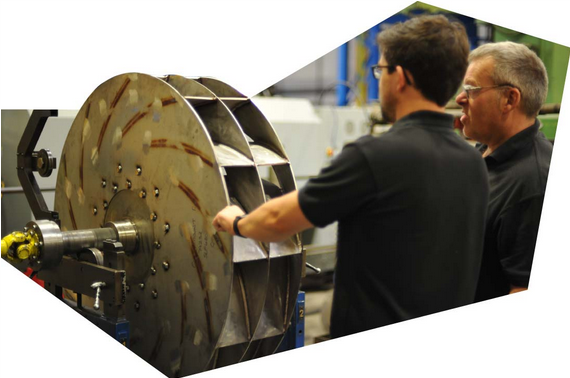

Dynamic Balancing

An in-house balancing capacity of 30 tonnes

All types of rotating parts can be accurately balanced on our high-precision machines, including rotors, impellers, fans, and shafts.

Specialist dynamic balancing with your team at WDB Ltd will improve the service life, accuracy, and quality of your machinery. We can identify and correct unbalanced components efficiently.

Balancing to ISO quality grades

Our in-house balancing capacity means we are able to balance any rotating equipment from just a few grams to 30 tonnes.

We can also achieve the lowest ISO quality tolerance over a wide range of service speeds.

Offering an unrivaled depth of experience

ISO9001:2015, AS9100 Rev D, and Safe Contractors accreditation, you can be guaranteed of quality dynamic balancing and engineering services.

You will benefit from over 50 years’ of experience in the dynamic balancing industry, from our expert team who carry out balancing services to a range of industries worldwide.

An in-house dynamic balancing service that is second-to-none

We pride ourselves on our excellent service to our customers, with short turnaround times to suit your requirements and a 24-hour breakdown service.

On completion of the job you will be provided with a Certificate of Conformity and detailed reports to suit your individual needs. Delivery and collection can also be arranged for you if required.

Non Destructive Testing

Reduce downtime and increase productivity

Our non destructive testing (NDT) services keep your assets up and running by identifying faults and rectifying them early to avoid unexpected downtime. As we all know, inactive machinery inevitably leads to lost revenue.

Effectively determine quality issues in a non-invasive manner

Evaluate the reliability of your assets without damaging or rendering them unfit for purpose.

Magnetic Particle Inspection (MPI)

Detecting surface and subsurface flaws in ferromagnetic materials

Our magnetic particle testing service can be used for examining all types of components, from small items such as castings and forgings to larger in-service components. This method of non destructive testing can identify surface breaking and slight sub-surface defects such as cracking and pores, particularly in welds, which may cause reductions in durability and lifespan.

Ensure regulatory compliance

Achieve complete compliance with industry regulations by identifying any non-compliant components.

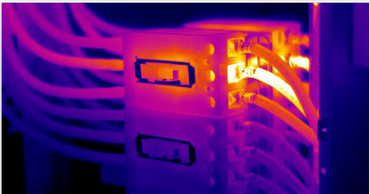

Thermography

Identify wear and tear, load imbalance, and damaged connections

Extend the life of equipment by locating anomalies in components prior to failure by precisely monitoring the wear and tear on bearings, conveyors, motors, pumps, compressors, electrical panels and connections.

Safe and accurate diagnoses of mechanical, electrical, refractory, and building defects

Thermography is a powerful, preventative maintenance technique used to measure the temperatures of electrical and mechanical systems using infrared radiation. Thermography also allows you to identify and prevent fire risk.

Receive detailed, actionable reporting

After carrying out thermographic inspection, you will be provided with a detailed report highlighting actionable, prioritised information with details of the fault.

Consultancy

Balancing can improve a rotor’s performance and extend the life of the machine.However, this procedure is often not planned into the design stage of the manufacturing process.

Your WDB Ltd team will work with you during the design stage to advise on the best method of balancing, balance correction, manufacturing method and grade.

Avoid redesigning and remanufacturing parts

Building in these provisions will prevent the need for costly remanufacturing of parts, unexpected downtime, and in turn improve a rotor’s performance and increase the life of the machine.

Contract Balancing

Whatever your requirement, whether it is simply advice, high volume batch production, one-off development parts, or an occasional repair, the WDB Ltd team is on hand to provide you with an expert, professional, and cost-effective contract dynamic balancing service.

An in-house capacity of 30 tonnes

With our range of high-precision vertical and horizontal balancing machines, we are able to balance any rotating part. This includes rotor balancing, impeller balancing and fan balancing. We also specialise in a wide range of shaft balancing, ranging from a few grams in weight up to 30 tonnes. We work to ISO grade, and over a wide range of service speeds.

Over 50 years’ experience

A range of in-house, on-site, and plant maintenance and machining services, combined with over 50 years’ experience, means that our highly qualified site team and experienced engineers are committed to achieving the highest levels of accuracy and reliability for you every time.

Detailed reporting, short turnaround times, and 24 hour breakdown service

As part of our service to our customers, you will be provided with a Certificate of Conformity as well as a detailed report on completion of the job. We will also work to short turnaround times to suit your requirements, and arrange delivery and collection if needed.

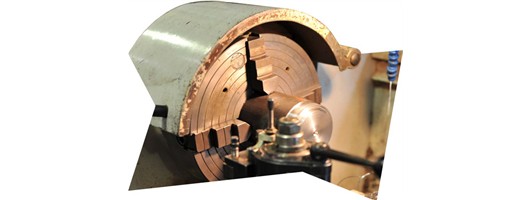

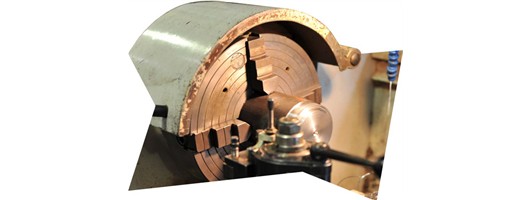

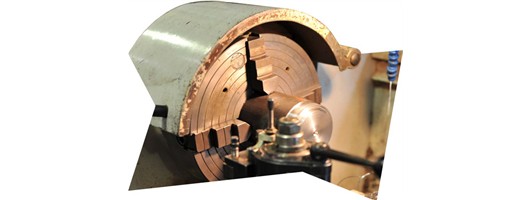

Machining Services

At WDB Ltd, no job is too small or too complex. We are able to manufacture custom designs based on your requirements, as well as reverse engineer drawings and components to replicate, manufacture, and balance.

Extensive machining facilities for design and manufacturing components

We offer extensive machining facilities on a range of large and small machine tools, with various ancillary equipment to suit your machining requirements.

Contract and one-off manufacturing backed up by CAD

Your WDB team will ensure you are provided with a high level of accuracy and precision at all times. Using CAD software, you will be able to visualise 2D and 3D drawings of your components before they are manufactured, giving you more control over the process, and fewer costly iterations.

Short lead time

We know what it’s like to manage short lead times without risking the quality of the final product. At WDB Ltd, we will work with you to ensure your time restraints are met without impacting the quality of service.

One-Off Prototypes

Using our expertise and specialist kit, we are able to balance test and dynamically balance individual prototype components and assemblies.

This provides your designers and manufacturers with crucial feedback, allowing them to adjust their designs to improve reliability and machine performance during development.

Quick turnaround to meet your timescales

We can facilitate same or next-day turnaround to meet your needs.

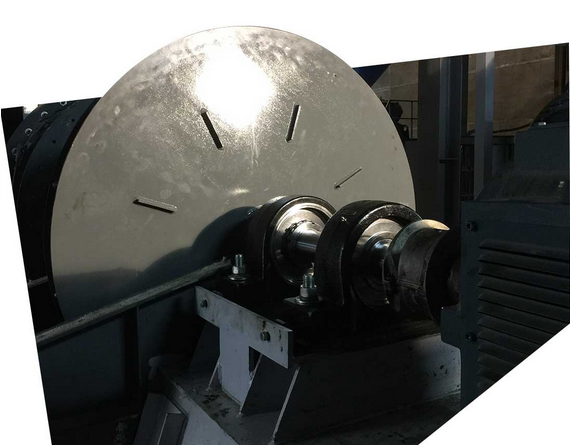

On-Site Balancing Services

Our experienced engineers will carry out dynamic balancing using portable balancing equipment to identify and rectify unbalance in your machinery quickly and accurately in its installed position.

This avoids the need to dismantle and reassemble the machine which would result in costly downtime.

Performance testing to identify cost savings

We also offer on site performance testing to assess the actual duty performed by any fan units, this allows us to establish any potential power, and therefore cost savings that can be made.

Repair and refurbishment

If you are planning an overhaul of your equipment, we can come to your site, measure impellers, shafts, pulleys, bearings, couplings, and supply as new. We can also refurbish plant and machinery as required in-situ.

Vibration Monitoring

Excessive and prolonged vibration, as well as the misalignment or imbalance of rotating elements can wear components prematurely, shorten their lifespan and create safety issues. Vibration monitoring allows you to detect these issues and react proactively, rather than reactively.

Improve the lifespan of your machinery

At WDB Ltd, we use vibration sensors to monitor the vibration levels of all types of rotating machinery including fans, pumps and motors. Monitoring this vibration is key to eliminating common performance problems in order to extend a machine’s lifespan, improve accuracy, and avoid system failure.

Vibration sensors for a range of industries

At WDB Ltd, we offer AC and 4-20mA sensors. These sensors are both ATEX and IEC Ex certified for use in both Group I (Mining) & Group II (Petrochemical) applications and will also operate in environments of inflammable gases, fumes, chemicals, powders and dust.

About us

Founded in 1968, WDB Ltd, also known as Wilkinson Dynamic Balancing Ltd, is the largest independent dynamic balancing provider in the UK.

Our specialist balancing solutions are delivered worldwide, ensuring the highest levels of accuracy and reliability. With over 50 years of balancing experience, we provide specialist solutions to industries such as aerospace, automotive, power generation, and petrochemical.

The following services are provided by our skilled team of engineers with the highest level of industry knowledge and the latest technology:

- Static & Dynamic Balancing

- Vibration Analysis

- On-Site Balancing

- Laser Shaft Alignment

- Machine Condition Monitoring

- Non-Destructive Testing

- Thermography

- On-Site Industrial Fan Repair & Replacement

- Site Testing & Commissioning

- 24-hour Breakdown Service

- Design & Manufacture of a Large Range of Industrial & Specialist Fans

30 Tonne In-House Capacity

With an in-house capacity of 30 tonnes in horizontal and vertical plane machines, WDB Ltd's high precision balancing machines can dynamically balance any rotating part, including rotors, impellers, fans, and shafts. We also have an extensive range of general machine tools, both conventional and CNC.

- Horizontal balancing capacity: 30 tonnes, 4.5m diameter x 8.5m long

- Vertical balancing capacity: 1000kg, 1.5m diameter

An ISO AS9100 Certified Company

We hold ISO90011:2015, AS9100 Rev D and Safe Contractors certification as well as adhere to stringent quality standards.

As a result, you can be assured that our products and services meet the internationally recognized aerospace quality standards.

An Unrivalled End-to-End Service

The process of balancing rotors improves their performance and increases their life, although it is rarely thought of or implemented in the manufacturing process during design.

To extend the service life, quality, and accuracy of your machinery, WDB Ltd offers a complete end-to-end service from initial enquiry to design, manufacturing, testing, and delivery to site.

Working Closely with a Range of Industries

We also work closely with leading academic institutions on research projects, providing expert advice, in addition to the aerospace, automotive, power generation, and petrochemical industries.

We are approved suppliers to Rolls-Royce PLC, Rolls-Royce Deutschland, Leonardo Helicopters, and Pratt & Whitney.

Images