Quick Links:

Products

Aerospace NDT Inspection

Our technicians provide florescent magnetic particle inspections to EN4179:2017

We have an extensive background in florescent MPI and process improvement techniques in NDT. This has largely been developed over the years whilst inspecting light and heavy machine guns.

Get in touch to find out how we can enhance your NDT experience; info@whendt.co.uk

Asset Integrity NDT Inspection

We work around your time frames to ensure as little or no downtime as possible.

In service defects are usually caused by stress fractures, fatigue or damage due to operator error.

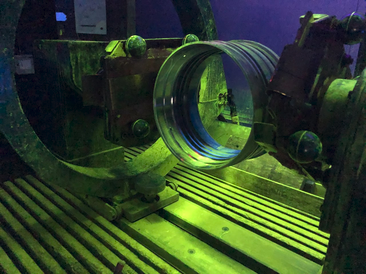

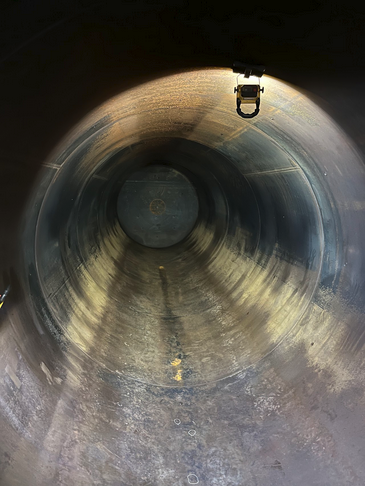

Boiler Inspection

Boiler, Tank and Plant Room inspection techniques

Ultrasonic thickness surveys are utilised to see if the pipe wall thickness is starting to corrode and or diminish.

Visual inspections are carried out with every in-service inspection. We comment on general condition of the pipe work and highlight any areas for concern.

Ultrasonic butt weld inspections are carried out to ensure the installation was carried out properly, ensuring the weldment is conforming.

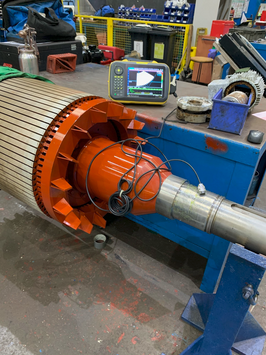

Phased Array Ultrasonic Inspections are used to inspect butt welds. This inspection has a high accuracy and is quicker than conventional ultrasonic inspections. Data is collected during the inspection and is presented to the client upon request.

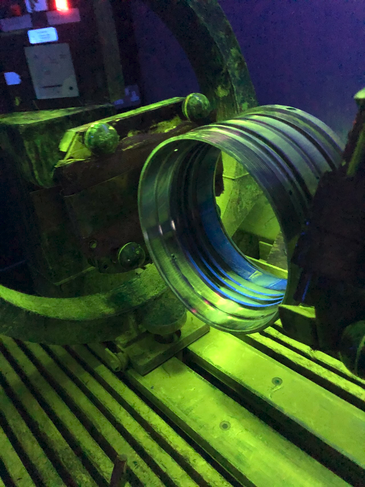

Magnetic Particle Inspection is a surface inspection method that is used on ferritic material with no paint present or removed. This inspection is very good at finding surface breaking defects and pin holes.

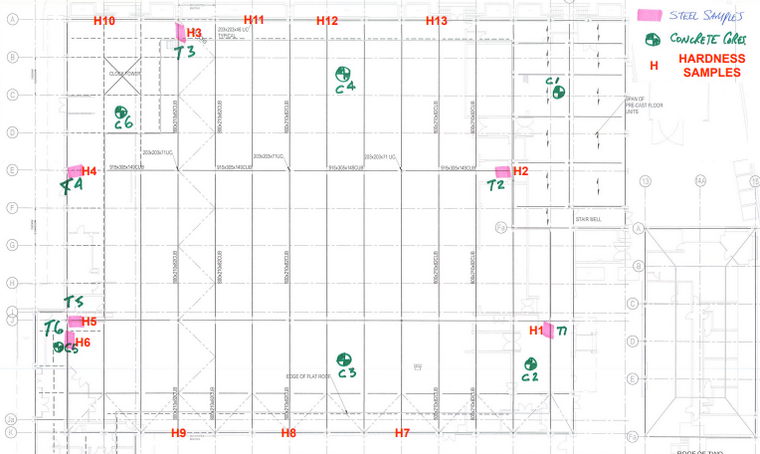

Concrete Testing & Inspection

Previous projects include; Leicester Square & Morrisons Folkestone.

Contact: info@whendt.co.uk to see how we can assist you with project requirements.

Crane NDT Inspection

We carry out Magnetic Particle, Ultrasonic, Dye Penetrant & Visual Inspection methods.

All or NDT technicians hold skilled CSCS cards, IPAF 3a & 3b and Working at height training.

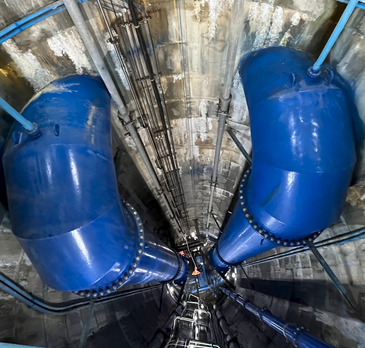

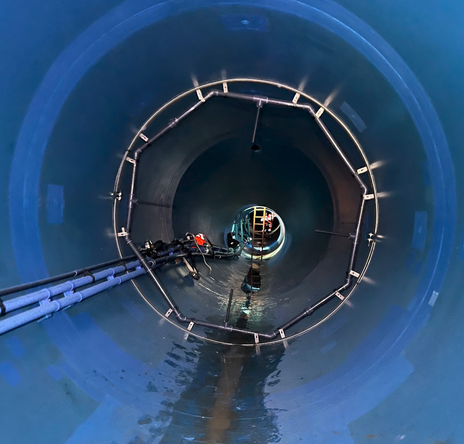

District Heating NDT Inspection

Our DH projects take us all over the UK and Ireland but the majority take place local to us in London.

MOB / DEMOB NDT Inspection

WHE NDT provide an efficient mobilisation and demobilisation NDT service for rigs and ships, operating in the maritime, Oil & Gas, and offshore power generation sectors - Be this planned maintenance or unplanned, we are able to deploy NDT Technicians at short notice to accommodate everyone.

Pipeline NDT Inspection

Our experienced NDT technicians carry out a multitude of testing methods, depending on application, environment and client specification.

Inspection methods used include;

Phased Array Ultrasonic Testing, Manual Ultrasonic Testing, Ultrasonic Thickness Surveys, Magnetic Particle Inspection, Dye Penetrant Inspection & Visual Inspection.

NDT Inspection Project Management & Consultancy

CONSULTANCY - Boasting extensive combined academic and work place experience, we offer Non Destructive Testing consultancy. At WHE NDT, we can solve clients most complex NDT issues, distinctively. We deliver strategy and implementation from a technical and business point of view, whether it be the Manufacturing or Power Generation industry, WHE NDT have you covered.

Structural Steel NDT Inspection

Our competitively priced services and experienced technicians make us a leader in this market. Our fully qualified inspection team hold skilled CSCS cards, Working form Height, IPAF 3a & 3b, in addition to PCN certificates in Non-Destructive Testing.

Inspection methods we commonly utilise on these projects include; Ultrasonic Testing - UT, Magnetic Particle Inspection - MPI, Dye Penetrant Inspection - DPI, Visual Testing - VT

For more information please get in touch; info@whendt.co.uk or +44 7398 638420

Weld Procedures & Welder Qualifications

Weld Procedure Specification is the formally written document which provides the welding party with the necessary information for the scope of work they have. This preliminary document is normally provided by the manufacturer, along with test pieces from each welder.

Weld Procedure Approval

Weld Procedure Approval is the next step in the process, whereby the preliminary procedure is reviewed and approved by the inspection body. The approved procedure will come as part of the Weld Procedure Approval Record.

WHE NDT are willing and able to provide this service at your request.

Welder Qualification

Welder Qualification is the final step, using test pieces provided by each welder. The welded components are inspected and tested by various NDT methods, alongside destructive mechanical tests.

We travel to our clients, working around your schedules, offering an efficient and great value service.

Welding Services

Some previous projects include;

Southbay Civil Engineering - Ridham Dock - Ground piles with sample extraction.

Total Lifting Solutions - Canadian Embassy - Heavy duty automotive lift repairs.

Heathrow Cranes - Jib repairs.

EG Martin - 60,000L Tank - Weld repairs.

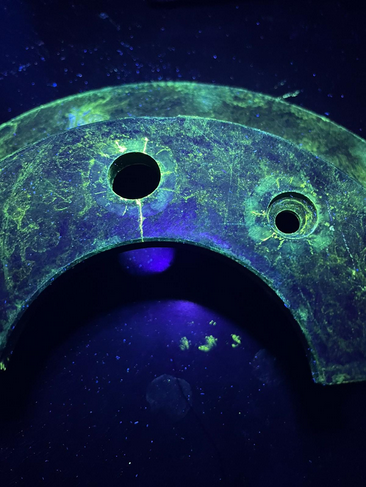

Magnetic Particle Inspection

MPI or MT is often used to certify welds to CE Marking standards and can be carried out on site by our competent technicians.

Inspection Standard - BS EN ISO 9934-1:2016

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Phased Array UT

To inspect a large volume of material, a conventional ultrasonic probe must be physically moved to scan the area of interest. In comparison, the beam from a PAUT probe can be focused and swept electronically, without the need to move the probe. The beam emission is controlled as the probe is made up of multiple small elements, each of which can be pulsed individually at calculated times. The term 'phased' refers to the timing, whilst the term array refers to the multiple elements.

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Dye Penetrant Inspection

Dye Penetrant inspections continue to be an effective and reliable inspection method for components such as; castings, forgings, machined parts and welds.

The two main Dye Penetrant Inspection methods we carry out are;

Colour Contrast Penetrant Inspection - Used for site work. Portable equipment. Very versatile. Good value. Great results.

Fluorescent Penetrant Inspection - Workshop based. Fixed equipment. Very high sensitivity. Great for large components.

All of our experienced inspectors are level 2 certified by the British Institute of Non-Destructive Testing.

Inspection Standard - BS EN ISO 3452-1:2013

Ultrasonic Weld Inspection

This form of Ultrasonic Inspection uses sound waves, both Shear and Longitudinal, to penetrate through the medium and find any discontinuities throughout the component. Our qualified and knowledgeable Ultrasonic Inspection Engineers will be able to perform this inspection and provide a report explaining their findings.

Inspection Standard - BS EN ISO 17640:2017

Acceptance Criteria - BS EN ISO 5817:2014

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Ultrasonic Thickness Measurement

Measuring the Ultrasonic thickness of a component is often useful in a variety of industrial situations. It is necessary for accurate weld evaluation, monitoring of tanks or pressure vessels, observation of ship hulls and examination of steel structures.

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Visual Inspection

VT can be used for internal and external surface inspection of a variety of components, including forgings, castings, pressure vessels, piping, and weldments.

This inspection is normally used in conjunction with a Magnetic Particle or Liquid Penetrant Inspection, as these are more thorough inspection methods.

VT is simple and much less technologically advanced in comparison to other NDT methods. The advantage to this is that less equipment is needed and costs can be kept down. VT is also one of the most reliable techniques, as a well-trained inspector can detect most signs of damage.

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Hardness Testing

WHE NDT are able to give a measurement in Leeb (HL), Brinell (HB), Vickers (HV) or Rockwell (HRA, HRB, HRC).

This test can be carried out on a wide variety of materials. Our operators are able to carry out this service on site or at our test facility.

If you require any further information, please do not hesitate to contact info@whendt.co.uk.

Tank & Plant Room Inspection Techniques

Visual inspections are carried out with every in-service inspection. We comment on general condition of the pipe work and highlight any areas for concern.

Ultrasonic butt weld inspections are carried out to ensure the installation was carried out properly, ensuring the weldment is conforming.

Phased Array Ultrasonic Inspections are used to inspect butt welds. This inspection has a high accuracy and is quicker than conventional ultrasonic inspections. Data is collected during the inspection and is presented to the client upon request.

Magnetic Particle Inspection is a surface inspection method that is used on ferritic material with no paint present or removed. This inspection is very good at finding surface breaking defects and pin holes.

About us

Our services include Magnetic Particle Inspection, Ultrasonic Weld Inspection, Phased Array UT, Penetrant Inspection, District Heating Inspection, Structural Steel Inspection, Pressure Vessel & Tank Inspection, and Crane NDT Inspection.

We are committed to providing efficient, reliable, and value-driven NDT services tailored to your business needs.

Our Services Include:

Aerospace NDT Inspection

We support the aerospace industry by providing NDT technicians for independent inspections, particularly to reduce lead times for BAE146 landing gear overhauls. Our technicians perform fluorescent magnetic particle inspections to EN4179:2017 standards, drawing on extensive experience and process improvement techniques developed through inspecting light and heavy machine guns.

Asset Integrity NDT Inspection

A major focus of our NDT services is in-service asset integrity, assessing current asset conditions to safeguard life and the environment. We work within your schedules to minimize downtime, addressing defects typically caused by stress fractures, fatigue, or operator error.

Boiler Inspection / Tank Inspection / Plant Room NDT Inspection

We provide essential boiler, tank, and plant room inspections, tailored for both new and existing systems. Our experienced technicians use various techniques, including ultrasonic thickness surveys to detect pipe corrosion, visual inspections to assess general pipework condition, and ultrasonic and phased array ultrasonic inspections for accurate weld evaluations. We also offer magnetic particle inspection for identifying surface defects in ferritic materials. Each method ensures thorough assessment and reliable results to maintain asset integrity.

Concrete Testing & Inspection

WHE NDT provides nationwide concrete testing and material investigation services, enabling engineers and designers to assess existing structural properties for informed design and planning.

Crane NDT Inspection

At WHE NDT, we conduct routine crane NDT inspections throughout London and across the UK to support our clients' asset management needs, ensuring their cranes are in optimal condition both during operation and before deployment on new projects. Our inspections employ magnetic particle, ultrasonic, dye penetrant, and visual inspection methods. All our NDT technicians are certified with CSCS cards, IPAF 3a & 3b qualifications, and comprehensive working-at-height training.

… And more.

We proudly serve sectors such as Defence, Aerospace, Power Generation, Construction, Rail, Fabrication, Engineering, and Manufacturing. Our technicians hold Level 2 PCN or CSWIP qualifications (ISO 9712) from the British Institute of Non-Destructive Testing, backed by practical and academic backgrounds through engineering-based apprenticeships and university education. We also have team members with advanced Level 3 qualifications, ensuring the highest standards of expertise.

With 24 years of combined experience, particularly in specialist power generation, district heating energy schemes, and structural high-rise inspections, we make it our responsibility to understand and meet all your requirements with a hassle-free service.

If you're unsure about what you need, we are here to guide you and ensure all your NDT needs are met efficiently.

Images