Company details for:

WK Precision Ltd

International House,

Waldon Way,

Holsworthy Industrial Estate,

Holsworthy,

Devon,

EX22 6ER,

United Kingdom

Quick Links:

Products

CNC Turning

Our team know how to handle a wide range of challenging materials and tight tolerances, so you can be sure that whatever your job involves, we’ve got the skills and equipment to handle it.

CNC Milling Horizontal & Vertical

Grinding & Honing

Volume Machining

Wire Erosion

Mass-Produced Steel Components

Our strong processes let us consistently deliver tens of thousands of units every month, and robust quality control ensured every piece was produced within tolerance to a high standard, and then packed and shipped on time.

Custom-Made Automotive Parts

These jobs are often unique, one-off items, but our strong prototyping ability and experience with small-run items lets us turn around high-quality parts fast − doing our bit to help keep some beautiful machines on the road.

Bespoke Steel Parts for Commercial Goods Firms

We advised on the best material for the job and then delivered a run of 5,000 pieces at a competitive rate.

We regularly supply a well known glass manufacturer of high quality glassware with polished stainless steel items to enhance some of their product lines.

About us

With more than 150 years of combined engineering experience, our team is well-equipped to meet any specification and offer expert advice on materials and design.

WK Precision is ISO 9001:2015 certified, ensuring that your components are manufactured to the highest standards in a safe and controlled environment.

Our Services Include:

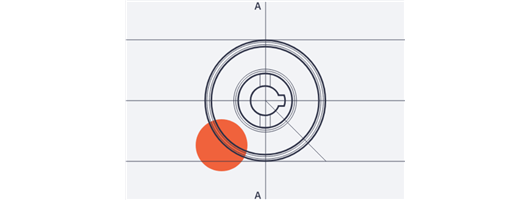

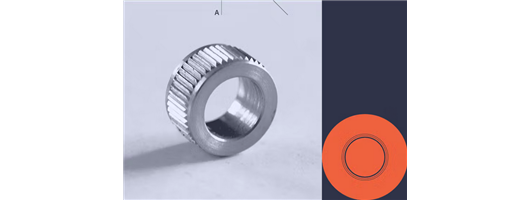

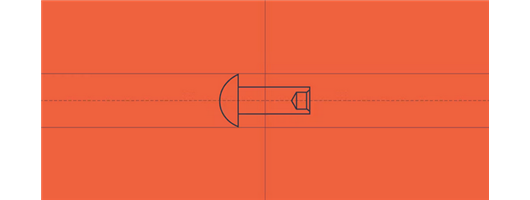

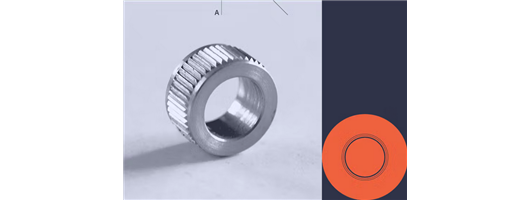

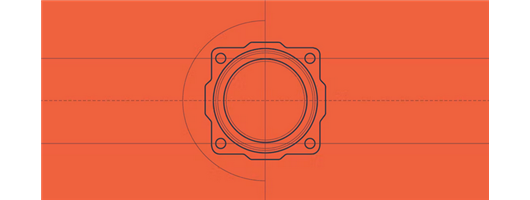

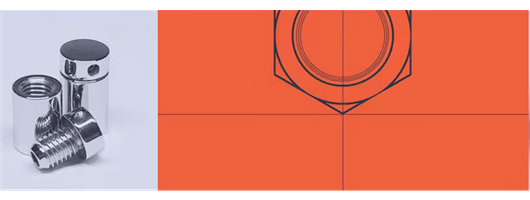

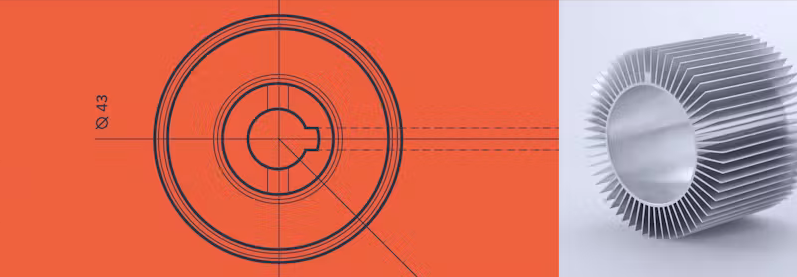

CNC Turning

Our CNC Turning department features three Nakamura machines, renowned for their reliability. These machines offer a maximum turning diameter of 330mm and a bar capacity of 65mm. Our team is experienced in working with a variety of challenging materials and precise tolerances, ensuring we have the expertise and equipment to manage any job.

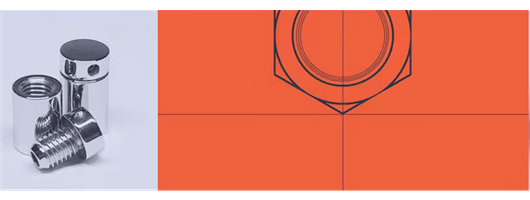

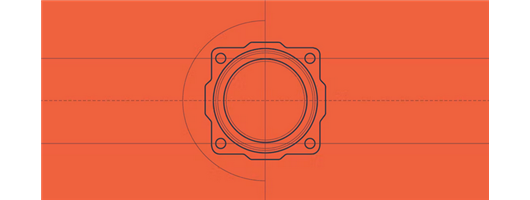

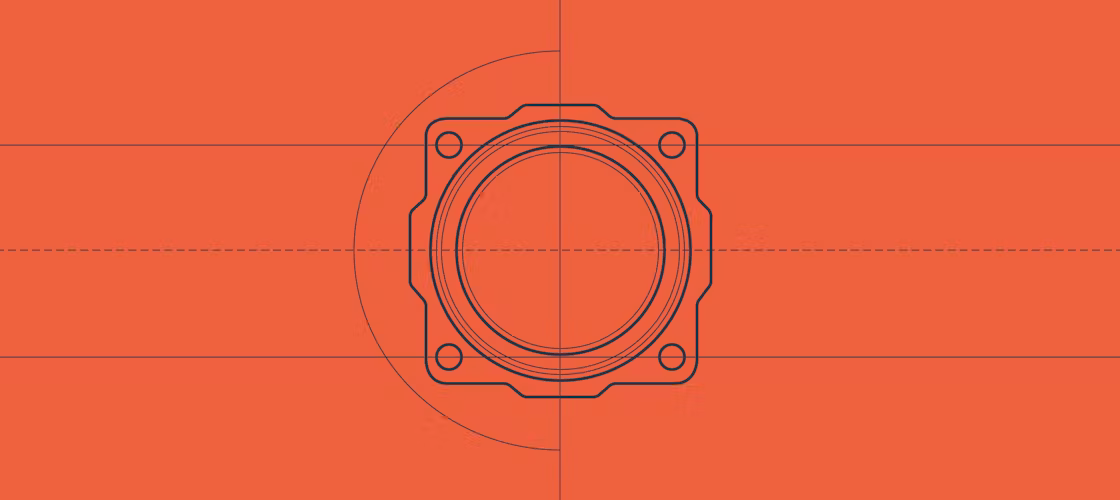

CNC Milling Horizontal & Vertical

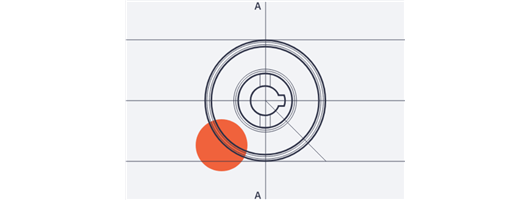

WK Precision excels in surface grinding, cylindrical grinding, and creep feed, along with specialised techniques like honing to achieve the ideal surface texture or geometric shape for a component.

Grinding & Honing

We use two BMC machines (20 & 30) to handle a diverse range of milling tasks.

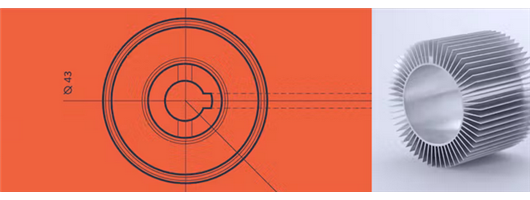

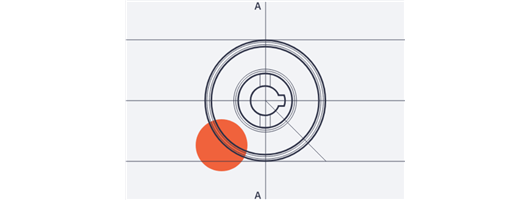

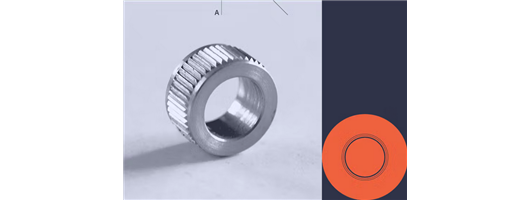

Volume Machining

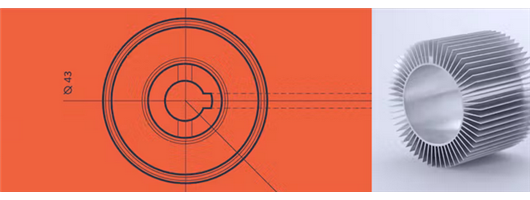

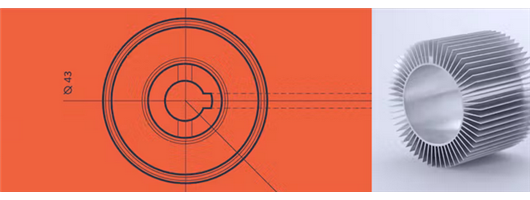

We utilise highly accurate Star sliding head machines, along with Davenport multi-spindle machines, and leverage our team's 150 years of experience to efficiently manage both small and large-volume projects, ensuring timely delivery and exceptional quality.

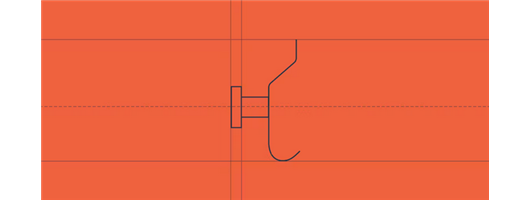

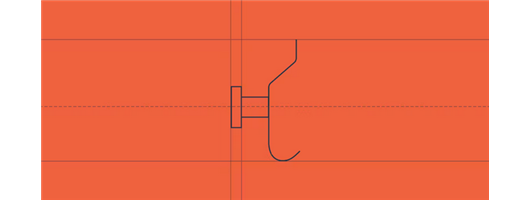

Wire Erosion

Our wire erosion facility enables us to perform highly precise cutting, shaping, and resizing on a variety of materials, both standard and exotic. This method allows us to produce components with exceptionally accurate tolerances in a consistent, repeatable manner.

For our volume turning services, we provide a PPAP service, delivering a complete dimensional report of a sample batch for your review and approval before the full production run. During the main run, each component is thoroughly inspected and guaranteed to meet the specified tolerances.

This ensures you can have peace of mind, knowing that each component will be delivered to the high standards you expect.

Get in touch with us for a quote on your project by using the form on our website, and we'll respond as soon as possible.

Images