Company details for:

HPS Product Recovery Solutions

Unit 46,

Evelyn Street,

Beeston,

Nottingham,

Nottinghamshire,

NG9 2EU,

United Kingdom

Quick Links:

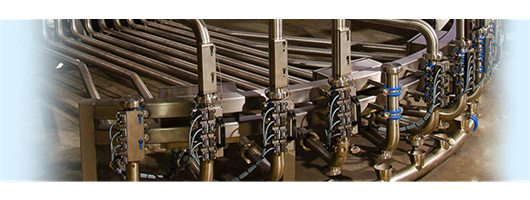

Products

Hygienic Pigs

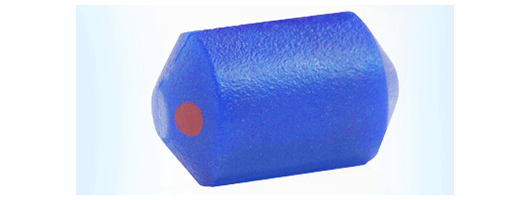

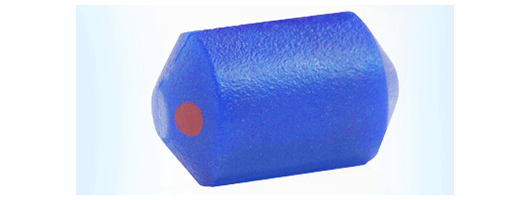

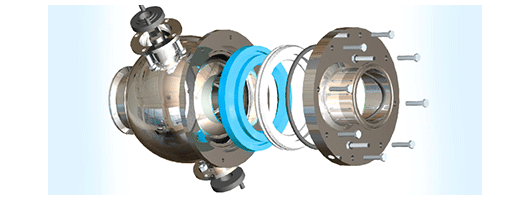

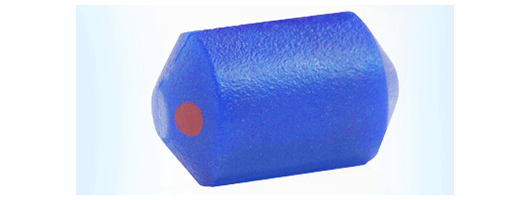

HPS patented hygienic process pigs are specially designed for highly effective, reliable and efficient hygienic (sometimes called sanitary) pipeline pigging, Used by many of the world’s largest liquid processing companies, they’re suitable for a wide range of products. These include food and beverages, chemicals, paints, coatings, lubricating oils, household and homecare products, personal care liquids, pastes and gels, cosmetics and many other applications.

Ideal for product recovery, liquid transfer and pipeline cleaning, HPS pigs have a typical recovery efficiency of up to 99.5% from full pipelines. They’re guaranteed for 30,000 metres or 18 miles of use (unmatched in the industry), and travel around bends while maintaining full body contact.

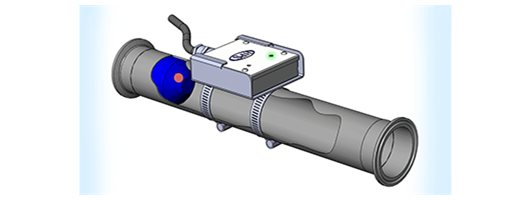

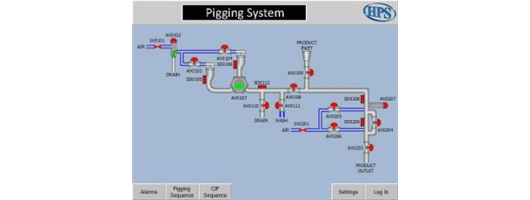

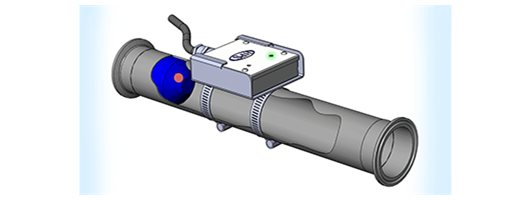

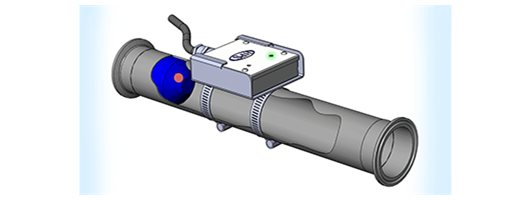

HPS AccuTect Pig Detector

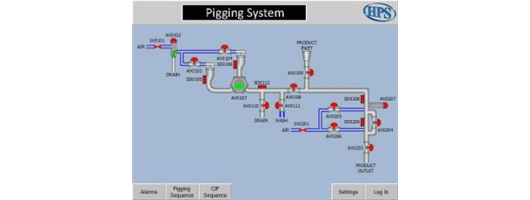

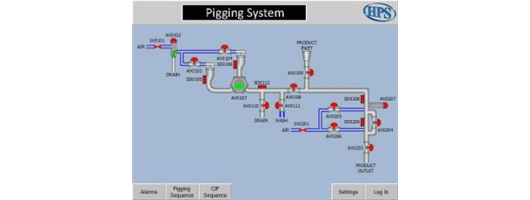

The HPS AccuTect pig detector (or pig detection system) is a device that determines the presence of an HPS pig when in it’s in close proximity. An essential component of pigging systems, pig detectors are usually located close to launch and receive stations, enabling highly efficient, safe and reliable operation − whether automated, semi-automated or manual.

The HPS AccuTect pig detector is the most advanced pig detection device available, determining the presence of an HPS pig when it’s in close proximity. Featuring an ultra-reliable detection signal, clear visual indication, and easy calibration, it’s ideal for hygienic (sanitary) and industrial environments.

Offering high levels of efficiency, reliability and performance, AccuTect pig detectors are used by many of the world’s largest liquid processing companies.

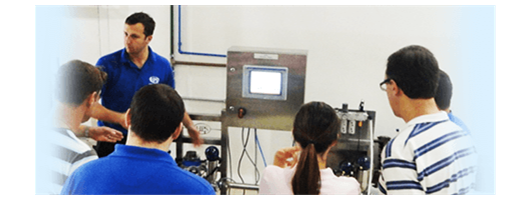

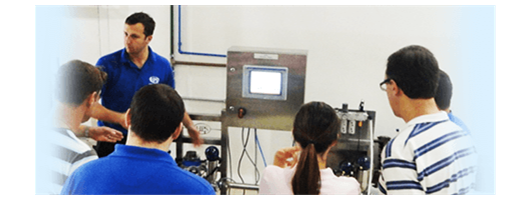

Pigging System Training

No matter how simple or complex your system is, we strongly recommend training for everyone who will work with your pigging, liquid transfer or process control solution.

Our high-quality product recovery and pigging system training is aimed at all personnel likely to operate, maintain or otherwise use the equipment. It ensures they fully understand the system and use it properly, effectively, and safely.

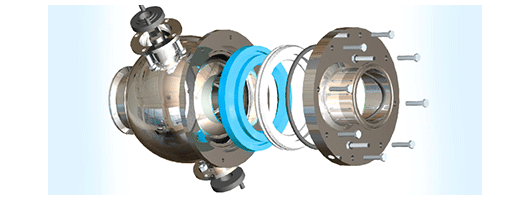

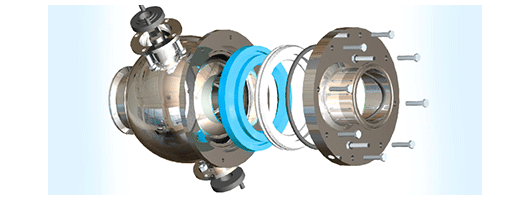

Pigging System Spares

From spare pigs and launch stations to seals and pig detectors, HPS carry a full stock of spare components and parts for hygienic and sanitary pigging systems.

Specifically set up to deal with all your spares questions, enquiries and orders, the HPS Spares Department provides top-quality service, help and support.

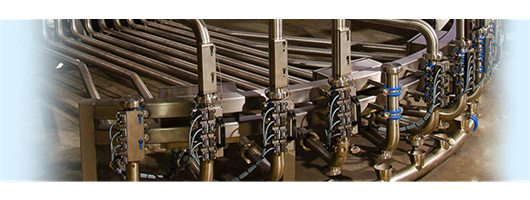

Hygienic Pigging Systems for Beverage Manufacturers

From soft drinks and fruit juices to wines, beers and spirits, HPS advanced liquid product recovery (‘pigging’) technology is the benchmark of the industry.

HPS pigging systems for beverage manufacturers are a convenient and highly cost-effective way of increasing yields, reducing waste, increasing production capacity, speeding up changeovers and CIP, and generally improving the process efficiency of beverage production.

As well as reducing product waste, HPS pigging systems also dramatically cut water and CiP chemical use.

Specially designed for beverage and hygienic (sanitary) applications, the unique HPS pig is made from food-grade materials and recovers up to 99.5% of residual liquids from full pipelines.

HPS pigs are bi-directional, and fully detectable, allowing full process automation. They do not contain solid magnets which can shatter or break, or fins which can allow product bypass and sometimes bend or tear.

HPS pigs can also travel around 1.5D bends while maintaining full body contact and so still fully recovering product.

From design to implementation, commissioning and after-sales support, HPS pigging and liquid transfer solutions are tailored to meet your exact needs and requirements.

To find out more about pigging systems for beverage manufacturers, contact HPS.

Process Pigging Systems for Lubricant and Grease Manufacturers

HPS is the world’s leading expert in process pigging systems for companies that process lubes and greases. Manufacturers across the world use our systems to manufacture motor oil, gearbox oil, hydraulic oils, general lubricants, greases and many other products.

If you work for a company that makes or processes lubricants, greases and similar products, HPS advanced liquid product recovery (pigging) technology will make your company more efficient.

Why? Because HPS pigging systems are the benchmark of the industry. Companies experience increased yields and capacity, cut waste, and improved operational efficiency and environmental sustainability.

The benefits of HPS pigging systems to lubricant and grease manufacturers include:

- Higher product yields and production capacity

- Reduced waste and associated disposal costs

- Lower risks of product contamination and cross-contamination

- Reduced production downtime for changeovers and cleaning

- Minimal lubricant re-work costs and maintained product integrity and value

- Lower cleaning and labour costs

Above all HPS pigging systems deliver a high ROI with a rapid payback period - typically between 6-12 months!

Hygienic Pigging Systems for Food Manufacturers

HPS advanced liquid product recovery technology (commonly referred to as pigging) is specially designed for use in hygienic and sanitary environments.

HPS pigging technology is in wide use in food manufacturing for its many benefits: it increases yields and capacity, reduces product and flush waste, speeds up changeover times and minimises contamination risks.

In addition, the unique HPS pig is made from food-grade materials and recovers up to 99.5% of residual liquids from full pipelines.

HPS pigs are bi-directional, and fully detectable, allowing full process automation. They do not contain solid magnets which can shatter or break, or fins which can allow product bypass and sometimes bend or tear.

HPS pigs can also travel around 1.5D bends while still fully recovering product.

Most importantly, food manufacturing companies that use HPS pigging technology gain a high return on their investment with extremely quick payback, usually in just a few months.

Process Pigging Systems for Paint and Coatings Manufacturers

If you work for a company that manufactures water or solvent-based paints, coatings, varnishes, pigments or similar liquids, HPS liquid product recovery systems will improve the efficiency, productivity, capacity, profitability and competitiveness of your plant and processes.

The benefits of pigging include:

- Preventing product contamination and cross-contamination

- Reducing product waste

- Increasing product yields

- Speeding up changeovers

- Cutting down labour-intensive cleaning processes

- Reducing flush water and CIP chemical waste

- Minimising waste disposal costs

HPS will design a system to meet the precise requirements of your process.

We also provide unique pigs for use in paint and coatings, the specification depending on the type of product you are processing, including the type of solvent (if applicable).

From design to implementation, commissioning and after-sales support, HPS is the world's leading specialist in pigging systems for paint and coatings manufacturers.

Hygienic Pigging Systems for Pet Food Manufacturers

HPS pigging technology is in wide use in the pet food industry. We supply our systems to a wide range of pet food manufacturers throughout the world.

HPS pigging systems for pet food deliver a wide range of benefits. These include:

- The removal of practically all traces of product residue from the pipeline

- Higher product yields and increased capacity

- Reduced waste processing and associated costs

- Improved lot traceability and batch control

- Less use of flush water and cleaning chemicals

- Faster changeovers and less production downtime

- Reliable prevention of cross-contamination

Most importantly, you'll get a high ROI with rapid payback from an HPS pigging system.

HPS specialist, high-performance hygienic (sanitary) pigs are made from food-grade materials and recover up to 99.5% of residual liquids from full pipelines.

HPS pigs are also bi-directional, and fully detectable, allowing process automation.

HPS pigs can also travel around 1.5D bends while still fully recovering product.

For more information, please get in touch with HPS − the world’s leading hygienic, sanitary and process pigging specialists.

Hygienic Pigging Systems for Chocolate and Confectionery Manufacturers

If you work for a company that makes or processes chocolate, candies, sweets, or other confectionery, HPS pigging technology will help you reduce product waste, make product changeover times faster, reduce the need for dedicated lines, increase operational efficiency and even improve lot control.

HPS pigging systems are used by many of the world’s best-known brands of chocolate, sweets and candies. This is because HPS pigging systems help chocolate and confectionery manufacturers through:

- High recovery rates (up to 99.5%)

- Reliable prevention of cross-contamination

- Increased yields

- Massively reduced waste and waste processing

- Reduced risks of products settling, solidifying and being wasted

- Less downtime

- Improved product quality

- Reduced butter, oil and flushing product usage

From design to implementation, commissioning and after-sales support, HPS provide a complete and comprehensive service to chocolate and confectionery manufacturers.

To find out more, please contact HPS.

Hygienic Pigging Systems for Homecare and Household Product Manufacturers

HPS pigging technology is used by many of the world’s best-known brands of household liquids, including white-label manufacturers. It’s used to improve efficiency, productivity and environmental sustainability during the manufacture and processing of products ranging from dishwasher fluid, washing up liquid, stain remover, floor cleaners, sanitisers, air fresheners, polish, bleaching agents, fabric softener, detergents and many other everyday household liquids.

HPS pigging systems deliver fast payback together with high ROI for homecare product manufacturers. This is through:

- Increased product yields and capacity

- Reduced waste and waste transport and disposal costs

- Faster changeovers with lower downtime

- Reduced risks of cross-contamination,

- Elimination of product aeration and foaming

- Reduced water and CIP cleaning chemical consumption

Hygienic Pigging Systems for Personal Care and Cosmetics Manufacturers

From hand creams, sanitisers, soaps, lotions and ointments to deodorants, toothpaste, oral care, shampoo and conditioners and HPS pigging systems improve the processes, efficiency and environmental sustainability of personal care and cosmetics manufacture by:

- Recovering product ingredients that would otherwise go to waste

- Increasing product yields and plant capacity

- Reducing waste disposal and treatment costs

- Speeding up cleaning and changeover times and reducing downtime

- Lowering water and cleaning chemical usage

HPS advanced pigging technology is proven to improve the processes and efficiency of personal care, beauty and cosmetics production plants throughout the world.

About us

HPS solutions are used in a wide variety of industries such as food, confectionery, cosmetics, chemicals, wine, soft drinks, spirits, beverages, paint, shampoo, homecare, pet foods and much more.

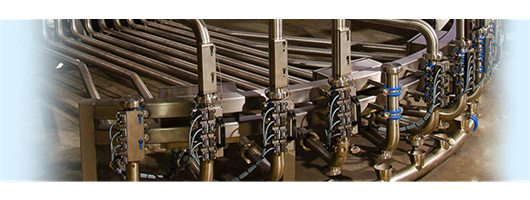

HPS provide complete pigging and product recovery solutions from design, manufacture and installation to support, spares and maintenance. We can retro-fit solutions on existing equipment, as well as brand new plant. For new installations we can offer expert advice on what you can do to maximise the systems potential and capacity for efficient product recovery.

Our unique flexible pigs, made from food-grade silicon products, typically recover up to 99.5% of product. They can travel around 90 degree pipe bends and withstand temperatures up to 200 degrees centigrade with no significant degradation. They’re also fully detectable and we can provide manually-operated pigging solutions or fully automated, computer-controlled systems.

Our Services & Equipment

- Pigging System Design

- Hygienic Pigs

- Pigging Automation

- Pig Detectors

- Pig Usage Software

- Piggable Diverter Valves

- Sanitary Ball Valves

- Piggable Rotomatrix

- Pigging System Training

- Maintenance & Support

- Pigging Through Hose

- Launch, Receive and Return Stations

- Automatic Product Distribution Systems

- Spares Service

Our clients include Loreal, Kraft, P&G, Unilever & Haribo.

With offices in the UK, USA and Australia and agents located worldwide, HPS Product Recovery can guarantee a first class service wherever you are.

Try our Pigging System Savings Calculator on our website and find out how much a pigging system could save you!

Images