Company details for:

Norbar Torque Tools Ltd

Wildmere Road,

Banbury,

Oxfordshire,

OX16 3JU,

United Kingdom

Quick Links:

Products

Torque Screwdrivers

With an accuracy that exceeds the requirement of ISO6789 (±6% for tools up to 10 N·m). Furthermore, they are engineered to retain this accuracy over many thousands of tightened cycles.

Available in N·m, lbf·in or production 'P' Type models

Torque Wrenches

In addition to the normal 'adjustable' torque wrenches, Norbar offer Production 'P' Type versions which can be pre-set and dedicated to a particular application. This setting system is designed to discourage unauthorised alteration.

All Norbar torque wrenches are offered as standard with a quality ratchet. For applications where interchangeable end fittings are required, 'Torque Handles' are also available in various models up to 650 N·m.

Manual Torque Multipliers

No gearbox is 100% efficient and so the velocity ratio (the number of turns that the input has to make to achieve one revolution of the output) is not the same as the torque multiplication ratio. Norbar multipliers are engineered such that each gear stage has a velocity ratio of typically 5.45:1 which results in a true torque multiplication factor of 5:1.

Torque output calculations are therefore a matter of simple arithmetic with little risk of incorrect bolt loading due to conversion errors. Other manufacturer's multipliers often require graphs or formulae to calculate the input torque to achieve a particular output.

The Norbar HandTorque is the most comprehensive multiplier range available. Standard products are available up to 47,500 N·m (35,000 lbf·ft) and 'specials' to 300,000 N·m (220,000 lbf·ft). A range of 'nose extensions' for reaching difficult to access bolts and full range of torque transducers for highly accurate torque monitoring are available.

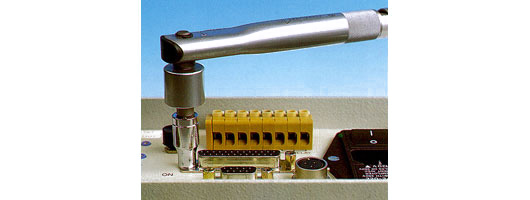

Pneumatic Torque Tools

PneuTorque operation is quiet - less than 85dB(A) with absolutely no impacting. These two factors make PneuTorques comfortable for the operator to use, reducing fatigue and consequently increasing safety.

PneuTorques provide accurate torque control - on a given joint they will stall repeatably to within ±5%. Using electronic shut off, this repeatability can be improved to ±2%.

The PneuTorque consists of a robust air motor driving a Norbar multiplier with three or more stages of epicyclic gearing.

Torque control is achieved by adjustment of the air pressure. An air pressure versus torque graph and a calibration certificate is supplied with each tool and allows specific torque values to be set. For more critical applications, PneuTorques can be fitted with a torque transducer and the precise torque output displayed. The tool can then be shut off at the desired torque either manually or automatically using suitable control circuitry.

Models are available up to 300,000 N·m (220,000 lbf·ft).

Electronic Torque Tools

Traditional electronic torque tools give vastly different results depending on the joint type. Norbar's intelligent joint sensing eliminates these issues so that you can be confident in your bolting work.

Reactions & Accessories for Multipliers

Nose Extensions are also available for Norbar HandTorque, PneuTorque and EvoTorque multipliers for situations where tool access is restricted.

Torque Measurement

All transducers up to 100,000 N·m are supplied as standard with a UKAS accredited calibration certificate from Norbar's in-house laboratory.

For customers who wish to take advantage of Norbar's transducers but have an existing, non Norbar display instrument, transducers can be provided with a mV/V calibration.

Norbar's instruments and transducers are complimented by a wide range of ancillary products. Within this group are the products that would be required to set up a torque calibration laboratory, for example, torque wrench loaders meeting ISO requirements and precision beam and weight systems for calibration of torque transducers.

Calibration Equipment

Torque is generated by the application of a known force at a known radius from the centre of rotation of the torque transducer.

Designed to remove potential sources of measurement error, these beams can be used to calibrate Norbar torque transducers, and torque transducers from other manufacturers (where design permits), as well as mechanical test devices. UKAS length certification is provided with each beam.

The Beams are designed with square drives machined to the top limit of ISO 2725:1987. This minimises any play between the beam and the transducer. However, a combination of square drive tolerances,

misalignment of fittings and elastic rotation of the transducer shaft inevitably cause the beam to rotate from the horizontal under load.

Norbar's Radius Ended Beams are designed with a +/-8% degree usable arc within which the calibration accuracy is unaffected.

Additionally the beams are designed to apply load on a vertical plane which cuts through the square drive inside the transducer. This minimises bending moments on the transducer and, for safe operation, ensures that the beam will not fall out of the transducer.

Harsh Environment Range

Ultrasonic Bolt Measurement

Ultrasonic measurement of bolt preload is made possible by introducing a sonic pulse at one end of the fastener and accurately measuring the time of flight (TOF) required for the echo to return from the opposite end. Using material constants, the USM-3 converts this TOF into an "ultrasonic length" of the fastener, providing a baseline from which future measurements will be made. When the fastener is tightened, the TOF increases and the USM-3 will again utilise material constants to eliminate the effects of stress and temperature variations on sound velocity, providing an accurate elongation or load measurement.

The USM-3 uses state of the art hardware and software to achieve these measurements with maximum automation, and minimizes the need for operator interpretation. Offering digital recording and transmission of data, in addition to analog signal output the USM-3 provides a complete system for measurement, recording, and control of fastener tension in the most demanding applications.

Calibration Certificate Software

Torque Calibration

Norbar has produced torque calibration equipment for over 60 years, and our UKAS accredited Laboratory is one of the finest in the world.

In addition to our UK laboratory we now we have Norbar torque calibration laboratories in the United States, Australia, Singapore and China for customers in those regions of the world and for whom quality service and fast turnaround time is paramount in seeking torque calibration.

All of our laboratories are assessed by government agencies to ISO 17025:2005.

Calibration Services

1. Should the device be in specification ’As Found’, a certificate will be raised and the device returned.

2. Should the device be out of specification, but capable of adjustment, it will be adjusted, ’As Left’ readings taken, and one certificate raised with ’As Found’ and ’As Left’ readings on it.

3. Should the device not be capable of adjustment, it will be returned, with a note on the certificate to that effect.

4. Should the device require repair, we will do so where possible, after consultation with the customer.

Norbar is accredited by UKAS for torque measurements between 0.005 N·m and 108,500 N·m or the imperial equivalents. Our Schedule of Accreditation gives further details.

UKAS certificates are issued under the authority of the United Kingdom Accreditation Service.

Accreditation by UKAS means that Norbar’s Laboratory has been assessed against internationally recognised standards to demonstrate its competence, impartiality and performance capability.

UKAS Accredited Laboratory

The hallmark of Norbar’s high standard of workmanship is clearly seen in the fact that we were the first torque equipment manufacturer to have an in-house UKAS accredited calibration laboratory. We have no intention of resting on our laurels, though, and take pride that we still provide the most comprehensive service available, ensuring we evolve to continue to meet your needs.

Norbar’s laboratory has approval for torques between 0.005 N·m and 108,500 N·m. and operates to BS EN ISO/IEC 17025:2005, which sets standards for the technical competence of the laboratory. This should not be confused with laboratories claiming ISO 9001:2008 which relates only to a laboratory's quality management systems.

After Sales Service

Service Replacement Policy

Slimline and Professional Models up to a capacity of 400 N·m and Industrial Torque Wrenches sent in for repair will be replaced by a Service Replacement Tool. It is not our policy to repair tools in these ranges.

Professional models with a capacity above 400 N·m will be repaired on a parts plus labour basis unless the service replacement cost would be lower.

New parts are used in the manufacture of service replacement tools and carry a twelve-month part and labour warranty and calibration certificate.

Spares Availability

Norbar offers over 150 different Spares Kits to support the longevity of their tools. In order to maintain the quality, performance, and peace of mind associated with their products Norbar recommend that only genuine Norbar spares are fitted to their tools.

Ultrasonic Measurement Devices

Hydraulic Tool Calibration Fixtures

EvoTorque 2

Electrode Wrenches

Torque Transducers

Battery Torque Tools

Harsh Environment Annular Transducers

Reaction Plates

Socket Retainers

Torque Wrench Calibrator

About us

Norbar Torque Tools offer solutions to torquing problems in a diverse range of industrial sectors including Oil &Gas, Aerospace, Mining, Energy (including wind generation), Manufacturing & Assembly, and Transportation (including wheels and tyres). Torque control is a key element of engineering reliability. In addition to torque wrenches, multipliers and transducers (sensors) we also sell complete sets of torque calibration equipment.

The Pneutorque® range of Pneumatic Multipliers offers a winning combination of vibration control and reduced sound pressure levels.

Norbar’s mission is to be the best torque tool company in the world. We aim to be respected, profitable and provide a great place to work. Norbar is a well established international company with UK roots.

In addition to this, most of Norbar's distributors offer repair and recalibration services and several have calibration accreditation by their local standards organisations.

Norbar − providing a global service for torque wrenches, torque multipliers, torque measurement, and torque calibration. The Voice of Torque Control.

UKAS accreditation 0256.

Our Torque product ranges includes;

Torque Screwdrivers − TTs Torque Screwdrivers.

Torque Wrenches − NorTorque, New Professional Wrenches, TT Wrenches, SL0 Wrenches, Industrial Wrenches, Professional 650 − 1500 Series, Professional Model 5, Tethered Torque Wrenches, Non-Magnetic, Electrode Wrenches, End Fittings, Repairs Kits, ‘P’ Type Handle Repair Kits and Torque Wrench Accessories.

Electronic Torque Wrenches − ProTronic, ProTronic Plus, ProTronic Plus Electronic Torque Screwdriver, ProTronic Plus Model 10 & 30 and NorTronic.

Manual Torque Multipliers − HT3, HT4, Compact Series and Standard Series.

Battery Torque Tools − EBT-52, EBT-72, EBT-80, EBT-92 and EBT Accessories.

Pneumatic Torque Tools − PTS Series, PTM Series, PT Standard Series and PneuTorque Accessories.

Electronic Torque Tools − EvoTorque 2 and Electronic Torque Multiplier Accessories.

Reactions & Accessories − Socket Retainers, Reaction Plates and Nose Extensions.

Torque Measurement − Tool Test Rigs, Torque Measurement Instruments, Hydraulic Tool Calibration Fixtures, Torque Transducers, Accessories for Transducers, Loaders and Electronic Ancillaries.

Calibration Equipment − Calibration Beams & Weights Laboratory Accessories.

Harsh Environment Range − Harsh Environment Instrument, Harsh Environment Static Transducers, Harsh Environment Annular Transducers, Harsh Environment TD Leads, TTL-HE Instrument and Transducers Kits, Intervention Tool Verification Kits, Intervention Tool Test Pots and Multipliers for Subsea.

Ultrasonic Bolt Measurement − Ultrasonic Measurement Devices, Ultrasonic Measurement Transducers, Ultrasonic Measurement Cables and Ultrasonic Measurement Ancillaries.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations