Company details for:

Focus Label Machinery Ltd

Kendryl Park,

Chapel Lane,

Bingham,

Nottingham,

Nottinghamshire,

NG13 8GF,

United Kingdom

Quick Links:

Products

Digital Inkjet & Hybrid Technology

The Reflex equipment provides a separate system of converting & finishing pre-printed digital labels from another source, such as HP Indigo, Xeikon, Memjet.

The d-Flex hybrid machine combines Ink Jet technology with a number of flexographic print configurations. This model is ideal for small volume orders, and can handle variable data and images with ease. Key features include Mono & 4 colour options, choice of web widths, UV drying systems and single colour rotary flexo head for pre−coating , printing and over varnish, & in line converting & finishing systems.

The e-Flex & Proflex Platforms can also integrate both mono & colour digital engines with a variety of options to suit specific applications with an emphasis on set up efficiency, waste reduction, low energy and running costs, and improved system controls. These Servo based technology equipment lines are digital print ready for a variety of applications including labels, films, packaging, tickets and cartons.

Accurio Label 230

No special materials or coatings, fixed cost consumables & servicing included, only pay for when & what you use.

At last a Digital system compliments any existing analogue label production departments.

SPEED: 23mts/min

PHOTOGRAPHIC IMAGING : 3600 x 1200 DPI/8 Bit

SOFTWARE : Colour management & Label Tools included

HALF TONES: superb tonal screens, gradients, and fine point text

SOLID COLOUR : Solid backgrounds with suitable gloss appearance, Consistent & Repeatable.

VARIABLE DATA: Clear barcodes & variable data per sheet, personalized labels.

MEDIA: wide range without Coatings/Pre-Treatment

MEDIA WIDTH : 330mm

APPLICATIONS: Labels , Tickets, Variable data , short run

COMPACT FOOTPRINT : 3.9mts x 1.9mts wide

FINISHING: Please refer to REFLEX for finishing, coating, foil, laminating, Roll or sheeting.

Accurio Label 440

Aimed largely at the mid to high-volume label producers. Important new developments include the ability to expand applications with white toner, extended job opportunities with continuous press runs up to 3000m, improved productivity with superfast print speeds of up to 130 feet per minute, and further running cost reductions thanks to even more durable parts life, as well as enhanced print quality.

The AccurioLabel 400 is available in 4- and 5-colour options and 330mm web width.

No special materials or coatings, fixed cost consumables & servicing included, only pay for when & what you use.

At last, a digital system compliments any existing analogue label production department.

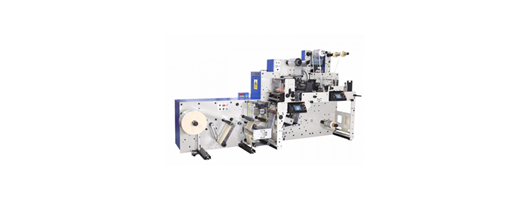

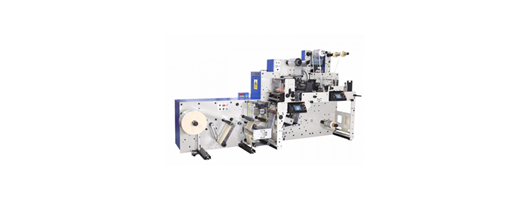

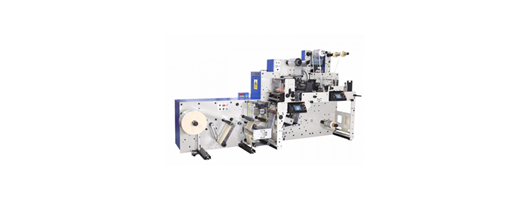

DFlex

Ink Jet technology combined with a flexo print station and full options labels can now be printed, coated & converted in line with no fuss at the press of a button.

High Speed Digital Ink Jet, 4 Colour Plus White option

Single colour Rotary flexo for printing & over varnish or coating

Servo Technology

Choice of web widths

UV Drying systems

Roll to Roll , Roll to Sheet converting

Applications: Labels, Security Labels , Packaging, Tickets.

DPack Machine

Fast turnaround of printed Papers, film & packaging substrates with high speed Ink Jet technology with no fuss at the press of a button.

Advanced RIP & Graphic Software options from GIS & COLOURGATE

High Speed Digital Ink Jet, 4 Colour Plus White option, CMYK, Mono

Single or Twin print head modules

Roll to Roll Servo Technology

Choice of web widths from 330mm

UV & LED Drying system options

Applications: Printed Papers, Films, Shrink Sleeves, Promotional Prints, Label Stock, Security Labels, Packaging, Tickets

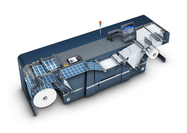

Reflex Machine & Digital Finishing Equipment

Digital Re-register of Pre-Printed webs at High Speed

Servo Technology

Choice of web widths

Combination IR & UV Drying systems

Roll to Roll , Roll to Sheet converting

Single Colour Printing & Coating

Applications: Labels, Security Labels , Finishing, Coating , Films, Packaging, Tickets

HMC: Flex Coater

Flexo Printing Modules: In Line

Coating Head: Motorised adjustment ,1 to 200gsm

Coating Equipment: Heated Hoses | Melt Tank | Drum Unloader

Water cooled Coating Rolls

UV DRYING: with Chill Rolls

Unwind: Integrated| Single |Multiple

Rewind: Single |Multiple

Tension Control: Servo- Automatic

Max. Speed: 300 ft/min (150m/min)

Full Servo drive system

Touch screen controls (HMI)

Recipe system for retained settings

Remote Diagnostics & upgrades

Security Tapes, Tamper Labels and specialist packaging applications

Customizable design for special applications

Our Hot Melt Coaters combine our expertise in coating technology and web tension control to consistently produce excellent results. With the advancements in adhesive technologies, especially UV curable adhesives, hot melt coaters are able to provide solutions that are efficient, environmentally friendly, and compact at a fraction of the cost of conventional solvent and water-based coaters. Combining Coating technology with the latest Flexo in-line printing systems provides a cost effective solution for Security tapes , Tamper Labels and specialist packaging applications.

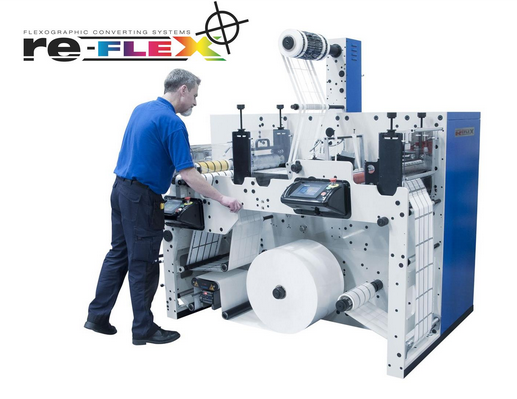

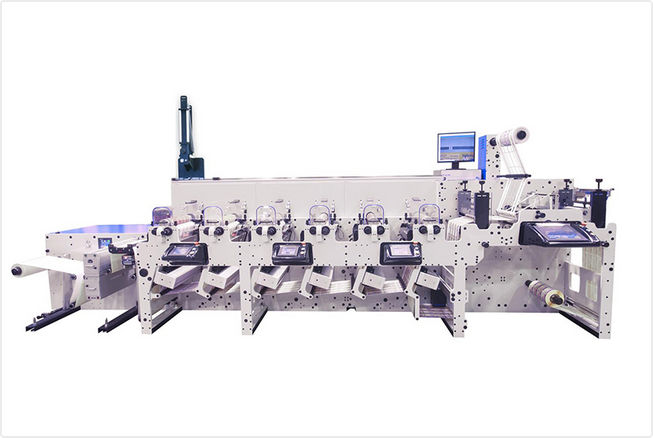

Proflex SE Machine

Modular 2 to 10 colours construction, Servo or Line shaft option

Choice of web widths

Combination IR, UV & led UV Drying systems with Chill Rolls

Roll to Roll, Roll to Sheet converting

Quick load Tooling for fast set ups & high quality Printing

Applications: Labels, Security Labels, Films, Packaging, Tickets, Cartons

eFlex Machine

The main features of the e-Flex machine include:

Twin Servo Technology

One touch set up & pre- register

Modular platform & Rail system for options

Choice of web widths

Combination Drying systems

Roll to Roll, Roll to Sheet converting

Applications: Labels, Security Labels, Films, Packaging, Tickets, Cartons

Inspection Rewind System Machine

Two machine styles

Web guide & splice table

Fully controllable web tensions

Scissor & Crush slitting

Twin rewind option

Programmable for label and or length count.

Applications: Finished rolls of Labels, Tickets, and Ribbons.

Ultrasonic Anilox Roll Cleaning Machine

Ultrasonic cleaning removes old Ink residue.

Quick & easy

No harsh chemicals

Brings rolls back to new condition.

Applications: cleaning Anilox Rolls, tools

Platemaking Systems Machine

System sizes from A4 to A1

Water & Solvent systems

Take control of you printing plate needs & quality

Applications: In house platemaking of Flexographic printing plates

Centraflex Machine

Compact Layout

Choice of widths

Choice of IR or UV Drying systems

Roll to Roll , Roll to Sheet converting

High quality Printing

Applications: Labels, Meat Casings, Films, Packaging, Tickets

Video Platemounting Machine

Some of the features of this video platemounting machine are listed below:

System available for a variety of machines & web widths, call for details.

Pin point Video accuracy

Plate clamp & positional adjustment

Applications :Plate mounting for press ready Cylinders

Latest technology

Technical equipment demonstrations

Job/Application proving

On site & off Site Training

Installation & Commissioning

D-Tex Digital Printing Systems

B4 Machines

On run register

Enclosed Ink Cartridge technology

High speed production output

IR Drying systems

Multi Ribbon Printing

Applications: Labels, Ribbons

LX Letterflex

Quick change cartridges for Colour & Jobs.

On run register

High speed production output

Combination Drying systems

Multi Ribbon Printing

In Line Label cutting systems

Applications: Labels, Ribbons, Elastics, Transfers, Dye Sublimation

NEW Touchscreen controls

Live Production Data monitoring

Global web & app based connectivity

LX Tagtrans

Multi-Colour Transfers in one pass

No Halo

Reduced waste

Two system options, or combination

Cost effective

Reduced waste

Applications: Tagless Labels, Heat Transfers, Decorative branding transfers

Tagtrans 150 Silk Screen

Multi-Colour Transfers in one pass

No Halo

Reduced waste

Two system options, or combination

Cost effective

Reduced waste

Applications: Tagless Labels, Heat Transfers, Decorative branding transfers

Tagtrans 225 Proscreen, Silk Screen

Single & Multi-Colour Halo free Transfers

Large print are for high production capacity

Servo drives for accurate Register control systems reducing waste.

New High capacity Thermo controlled drying system

Safety Compliant Inks (Water & Solvent)

Screen & Rotary Printing system options, or combination

Applications: Tagless Labels, Heat Transfers, Decorative branding transfers

TTC100 − Ultrasonic Cutting Machine

Ultrasonic cutting

Key pad programming for cut length

Link up Kit for Thermal Transfer printer (Print & Cut)

Single Cut/ Folding options.

Applications: Garment Labels, Decorative Ribbons.

Ultrasonic Anilox Roll Cleaning Machine

Ultrasonic cleaning removes old Ink residue.

Quick & easy

No harsh chemicals

Brings rolls back to new condition.

Applications: cleaning Anilox Rolls, tools

Platemaking Systems Machine

System sizes from A4 to A1

Water & Solvent systems

Take control of you printing plate needs & quality

Applications: In house platemaking of Flexographic printing plates

Fabric Curing Oven Machine

Some other features of this machine are:

Two system sizes

Thermostatic control

Fumes exhaust

Mechanical convection

Fully timed & temperature Programmable

Flexible Packaging

Our range of machinery allows for the efficient and cost-effective production of a wide range of packaging including sugar & food sachets, protective wrap and film and meat casings.

Focus Label Machinery provide a range of central impression flexographic machines which are ideal for high-quality printing on demanding substrates such as flexible packaging. Centraflex equipment has a compact layout with a choice of widths and either IR or UV drying systems.

The Proflex modular range of printing equipment offers a range of options for a variety of production requirements and is available with Servo drive or line shaft technology. Also available with IR or UV drying systems and roll-to-roll and roll-to-sheet converting capabilities, up to 10 colours high quality, narrow web printing is possible at a competitive price.

About us

We design, manufacture, and install a wide range of label printing machines, including inline, heat transfer, silk screen printing, and rewinding machines. Whatever your requirements, we can meet them.

Every machine we create is tailored to meet the specific needs of our customers. Our designs allow for new modules to be added, removed, or modified, enabling adaptation to the evolving requirements of your clients.

Our customised label printing machinery provides the perfect solution for various applications, including:

Cold Foil

Cold foil printing, or cold foil stamping, is a contemporary technique for applying metallic foil to a substrate, enhancing the visual appeal of the final product. This process is particularly well-suited for low-cost projects that use gold or metallised ink, which often results in a matte finish lacking the vibrancy of true foil. However, with a diverse range of cold foils available, the creative possibilities are limitless.

Peel & Reveal

In certain labeling scenarios, there may be a necessity−sometimes legally required−to include extensive information and data that cannot realistically fit on a single-label face. This is commonly seen in the pharmaceutical and chemical industries, where multi-page labels are prevalent. This trend is spreading to other sectors, offering a creative opportunity for those willing to invest time and technology. Here, Focus shares insights into one of the solutions available for Peel & Reveal label applications using our Flexo and Digital presses. The only limit is your imagination.

Flexible Packaging

Bags, envelopes, pouches, sachets, wraps, and similar items made from flexible materials like film, foil, or paper take on a pliable shape once filled and sealed. Our machinery enables the efficient and cost-effective production of various packaging solutions, including food sachets, protective wraps and films, and meat casings.

Heat Transfers Machines

A heat transfer machine, or heat press, is a device that applies a design to an item using heat and pressure. Typically, the design is printed on a paper or synthetic carrier, which is then transferred to the target item, usually textiles that will come into direct contact with the skin, such as underwear, swimwear, sportswear, and T-shirts.

Meat Casings

Casings are flexible cylindrical containers designed to hold sausage or meat mixtures. Manufactured artificial casings, made from cellulose, collagen, or synthetic materials, are frequently printed to promote specific brands and enhance value. They not only offer a space for product information and manufacturer highlights but also protect the contents during storage.

... And more.

At Focus Label Machinery Ltd, we take pride in delivering exceptional customer service alongside our high-quality products. If you need anything from us, please don’t hesitate to reach out.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations