Company details for:

HpE Process Ltd

Unit N2, Gildersome Spur,

Gildersome,

Morley,

Leeds,

West Yorkshire,

LS27 7JZ,

United Kingdom

Quick Links:

Products

Hygienic Pumps

Waste and loss of production are two of the biggest barriers they face. HpE Process has been a trusted partner and adept solution provider to High Street brands for over 30 years. We have helped manufacturers reduce waste and improve reliability, boosting productivity with bespoke hygienic pump systems designed around customers’ requirements. Incorporating personnel training the team offers a complete hygienic pumps system design, production, installation, maintenance and operation process to deliver maximum economic benefit

In a sector under constant scrutiny, HpE Process has delivered hygienic pump solutions with a quick return on investment, in many cases less than one year, ensuring that systems are commercially viable.

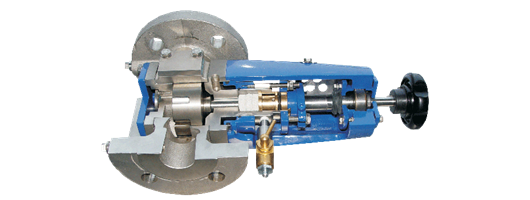

Versaline Flow Meter

The flow meter comes complete with hygienic Tri Clamp and RJT connections. All wetted parts are precision machined from Solid Stainless-Steel material with no castings to provide excellent long term viability, even in harsh applications.

Typical liquid food installations include:

Syrups

Waters

Oils

Food Stuff

Vinegars

Integrated Solutions

Food manufacture is still a labour-intensive process for many and in a climate where access to cheaper migrant labour is going to be restricted more & more, there is a need for cost-effective equipment that can provide tangible cost savings in food manufacturing.

With over 30 years supplying hygienic fluid handlings components to the industry, we fully understand the process industry & its requirements. The team is very experienced and is able to interpret customer requirements before supplying equipment that fits.

Well known in the industry as a supplier of hygienic Valves, Tube, Fittings, Pumps, Manways and Tank Equipment, we provide real cost-effective and practical solutions, we know the demands of the industry and what it means for our customers to meet processing standards and achieve sustainable production.

We recently launched our ‘Integrated Solutions’ a range of modular plug & play packages for customers to add to their factory processes.

CIP Skid Systems

A typical system will include an installation tank, CIP send tank, CIP return pump, Dosing Pump, Heating coil, Butterfly valves (Manual or Automatic) and a control panel.

Pasteurisers

Pigging Systems

Pigging allows these volumes, which are often under-estimated, to be recovered and sold

Rapid return on investment

Strong reduction in effluent volumes

Productivity increases

Decrease in cleaning cycle times

Improved traceability

Perfect recovery of residual fluids (liquids, viscous fluids, and fluids with markers)

Equipment and constructions tailored to the customer’s use, from DN 12 to DN 300, Hygienic, CIP, SIP, Low energy requirements, Low maintenance and operation costs.

Fully engineered systems possible:

study of functional analyses

drafting the pipework specifications

commissioning and user training.

Hygienic Tubes & Fittings

We have been a major stock holder of stainless steel hygienic tube and fittings for over 25 years, in that time we have always maintained strict standards on these products, meeting or exceeding national and international standards.

Our products combine high-quality materials, manufactured by state of the art technologies and certified processes. The tubing we supply is true process tube, not exhaust or architectural grade that has been polished up.

HpE offer an unsurpassed level of advice and high quality products in sectors as diverse as household, food and personal care that has enabled manufacturers to install effective systems that deliver uninterrupted production. As down time is cut, waste is minimised and the investment is quickly repaid within a shorter than expected period of time, delivering commercially viable results.

Hygienic Valves

Different products demand different solutions. For example, products with large solids can’t pass through a butterfly valve but a ball valve is not and can never be, fully hygienic or cleanable without being disassembled.

Our valves deliver a free flow of any product in production while providing cost savings through minimum downtime when cleaning the lines.

Alongside the hygienic valves, we supply aseptic sampling valves, tank outlet valves, as well as, industrial valves which include ball valves, gate valves, check valves and many more.

Working with partners such as Evoguard who use high grade and innovative technology to create the best conditions for the utmost quality.

Spares and fittings for Valves are available, including actuators, control heads, seals, etc

Manways & Tank Equipment

What truly differentiates HpE from competitors is the combination of having more than 150 years of combined technical expertise and the largest product range available from any source. We don’t just supply a manway/access door we supply a solution.

Tanks & vessels also need to be fitted with other ancillary equipment such as product inlet valves, product outlet valves, sampling valves, pressure/vacuum relief valves, sight glasses (with or without lights), mixers / agitators and cleaning equipment. Here again, we have the largest range of tank specific products available from any single UK source.

The increasing popularity for regional and real ales has boosted a need for tanks and tank equipment. We have become a leader in its field with more than 500 tank components including static and rotary sprayballs, sight-glasses, mixers and tank outlet valves. Coupled with the company’s understanding of the right part for the right job, our customers are guaranteed the best possible support.

Hygienic Mixers

In order for us to supply the industry with leading products, we are always keen to work with reliable and established partners. Our partnership with trusted manufacturers allows us to offer tailor-made solutions through CFD, constantly-improving mixing calculation tools and consistent experience in order to meet the specific needs of customers for new equipment or upgrading existing fleets and customer service.

Centrifugal Pumps

The centrifugal pump is in many ways the “backbone” of any liquids processing industry. In the food, beverage and pharmaceutical industries, the particular requirements for hygiene, reliability and efficiency mean that the KPA range is without doubt the best option available.

Diaphragm Pumps

AISIBOXER

Air-operated double diaphragm pumps for the Food and Beverage Sectors.

Line of positive displacement pumps mechanically polished AISI 316 L with surface finish of less than <0.8µm.

Max Flow Rate: 340L/Min

Max Air Supply: 8 Bar

Max Head: 80M

Max Suction from Negative Head − Dry Running: 2.5M

Max Suction from Negative Head − with Pump on: 9.5M

Max diameter of suspended solids:19.86 MM

SANIBOXER

Max Flow Rate: 340 L/Min

Max Air Supply: 8 Bar

Max Head: 80M

Max Suction from Negative Head − Dry Running: 2.5M

Max Suction from Negative Head − with Pump on: 9.5M

Full Flow

The line of compressed air pumps for the food, meat and poultry sectors, suitable for handling liquids and fluids containing large suspended solids.

This diaphragm pump is operated by compressed air and constructed in mechanically polished AISI 316L with surface finish lower thank <0.8µ. All the features of the FullFlow pump comply with FDA requirements.

Max diameter of suspended solids: 19.86MM

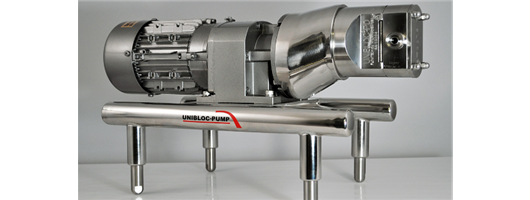

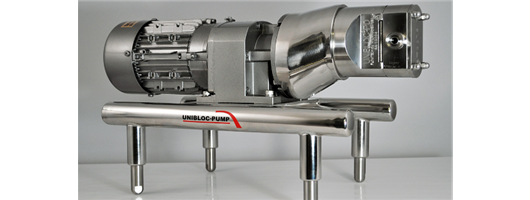

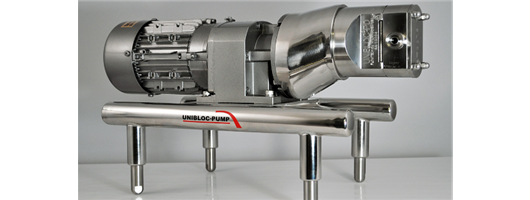

Gear Pumps

The Unibloc gear pump is a simpler and more cost effective version of the Unibloc Lobe pump using only a single seal and designed for simplicity strip-down cleaning. It is ideal for OEM’s as a feed pump for low to medium viscosity products..

Rotary Lobe Pumps

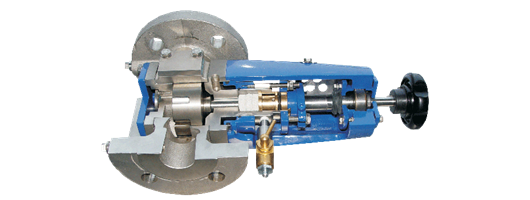

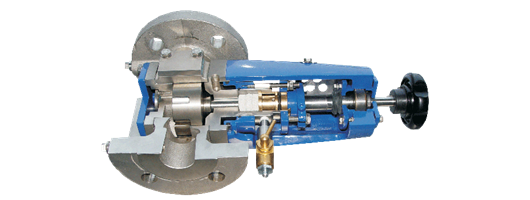

Twin Screw Pumps

The pump is gentle on the product and imparts much less shear than rotary lobe pumps. It is perfect for use in the food and drinks industry and has proved itself on products such as juice concentrate, mayonnaise, butter and spreads, peanut butter, chocolate, fondant cream, soups and sauces, biotech cell cultures, pharmaceutical creams and toothpaste.

Pump & Valve Service Repair

Once confirmed, the job is moved to our clean room facility, where re-assembly is carried out. We can perform static pressure tests, dynamic pressure and flow testing (for pumps). Items can be sanitised on re-build or after testing.

Our engineers can work on any manufactured pump, Centrifugal, Rotary Lobe, Twin Screw and other Hygienic Pumps.

You are able to purchase pumps online from our Brewline website.

Special Fabrication

All work is done to food standards and where appropriate, we use 3A and EHEDG guidelines.

Our 3D CAD facilities allow us to model jobs and seek client approval before fabrication work starts.

About us

HpE Process Ltd was formed when we noticed the effect that manufacturing downtime was having on production and waste, causing a loss and costing businesses money.

Our products include Centrifugal Pumps, Diaphram Pumps, Dosing Pumps, Gear Pumps, Lobe Pumps, Piston Pumps, Progressive Pumps, Screw Pumps, Premisphere Recovery Systems, Hygienic Process Tubes and Fittings, Pigging Systems, Valves & Manways & Tank Equipment.

Our experienced work force are able to provide Special Fabrication and Servicing and Repairs on both pumps and valves. Work is carried out at our head office in Morley, Leeds.

HpE Process Ltd’s mission is to solve all your hygienic fluid handling process problems.

We have an experienced and independent technical team who will design a bespoke solution drawing on our comprehensive range of proven products from the world’s leading manufacturers and in turn reducing plant downtime and waste.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations