Company details for:

Tampo Ltd

Oriel House, Block F,

Sunbury Business Centre,

Brooklands Close,

Sunbury-on-Thames,

Surrey,

TW16 7DX,

United Kingdom

Quick Links:

Products

PP21N - Entry Level Single & Multicolour Machines

Features

- Single or 2 color user-friendly pad printer

- Rigid aluminium casting machine frame

- Use sealed ink cup or open ink tray set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Membrane switch control panel

- Automatic pad clean with programmable cleaning cycle (on ink cup model only)

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

HVA 150 - Entry Level Single & Multicolour Machines

- Single or multi-color automatic pad printer

- Rigid aluminum casting machine frame

- Use sealed ink cup or open ink tray setup

- Compatible with long life, economy of Green plate,

- 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Microprocessor with membrane switch control panel

- Automatic pad clean with programmable cleaning cycle (on ink cup model only)

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depths

- Newly improved MS-150 machine stand enhances stability

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

Turbo 165 - Industrial Single & Multicolour Machines

- Single color large image pad printer

- Rigid all steel fabricated structure

- Both ink cup plateform and pad carriage move in/out for maximum throat depth

- Pneumatic pad cylinder & pad in I our carriage

- Use sealed ink cup set up (up to print 0155 mm image)

- Able to use laser engraved Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke and speed adjustment

- Print functions: double ink or print, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Heavy duty guide rail and runner blocks ensure friction-free movement

- Able to print the largest image amount machines of it’s size

Turbo 125 - Industrial Single & Multicolour Machines

- Single color automatic pad printer

- Rigid aluminium cast machine frame

- Platform in/out movement

- Pneumatic power machine operation

- Use sealed ink cup system

- Able to use laser engraved Green plate, thin steel plate,

- 10 mm steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke & speed adjustment

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

Turbo 90 - Industrial Single & Multicolour Machines

- Rigid aluminium cast machine frame

- Wide machine stand

- Platform in/out movement

- Pneumatic power machine operation

- Use sealed ink cup system

- Able to use laser engraved Green plate, thin steel plate, 10 mm steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke & speed adjustment

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

PP150 - Industrial Single & Multicolour Machines

- Light weight, rigid aluminium cast machine frame

- Use sealed ink cup or open ink tray set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for fast job change

- Membrane switch control panel

- Preprogrammed with 44 stored print options (special program on request)

- Dwell function valve for texture surface printing

- Variable pad delay prior to printing to maximize ink transfer

- Automatic pad clean with programmable cleaning cycle (on ink cup model only)

- Pad stroke & speed adjustment

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Emergency power shut-off

- Hardened ground steel shaft with impregnated bushing ensure

friction-free movement

- High speed and smooth machine operations

- Easily converted to 2, 3, 4 or 5 color machine with shuttle attachment or carousel conveyor

G Turbo 650 - Premium Industrial Single & Multicolour Machines

- Turbo pad clean design for multi-color printing

- Revolutionary Granite stone machine structure for performance & stability as well as protect our environment

- Both pad & printing plate platform in I out design for max. product size

- Four independent pad cylinders

- Pneumatic pad in I out carriage

- Servo drive product shuttle attachment

- Four sealed ink cup set up

- Able to use laser engraved Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control with large touch screen panel

- Programmable pad cleaning cycle

- Programmable pad stroke and speed adjustment

- Dwell and delay time

- Complete cabinate with light beam curtain (Optional)

G Turbo 350 - Premium Industrial Single & Multicolour

- Revolutionary Granite stone machine structure for performance & stability as well as protect our environment

- Both pad & printing plate platform in I out design for max. product size

- Two independent pad cylinders

- Pneumatic pad in I out carriage

- Pneumatic shuttle attachment

- Two sealed ink cup set up

- Able to use laser engraved Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

PLC control with large touch screen panel

- Programmable pad cleaning cycle

- Programmable pad stroke and speed adjustment

- Dwell and delay time

- Complete cabinet with light beam curtain (Optional)

G Turbo 130 - Premium Industrial Single & Multicolour

- Single color automatic pad printer

- Granite stone machine structure for performance & stability as well as protect our environment

- Wide machine stand

- Platform in/out movement

- Pneumatic power machine operation

- Use sealed ink cup system

- Able to use laser engraved Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke & speed adjustment

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

G Turbo 90S-2 - Premium Indsutrial Single & Multicolour

- 2 color pneumatic shuttle attachment

- Granite stone machine structure for performance & stability as well as protect our environment

- Wide machine stand

- Two independent pad cylinders

- Platform in/out movement

- Pneumatic power machine operation

- Use sealed ink cup system

- Able to use laser engraved Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- PLC control touch screen panel

- Automatic pad clean with programmable cleaning cycle

- Pad stroke & speed adjustment

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

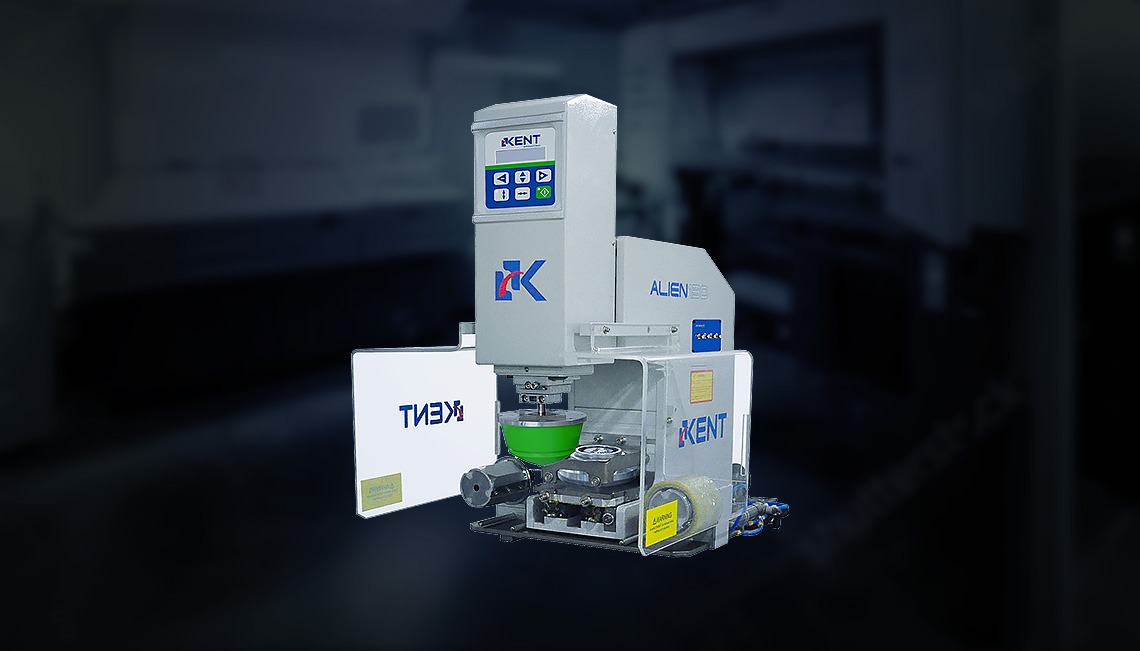

Alien 130 - Alien High Speed Series

- Rigid aluminium casting machine frame

- Pneumatic pad stroke

- Use sealed ink cup set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin - steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Fast setup, snap-on plate change

- Automatic pad cleaning with programmable cleaning cycle

- APS : Automatic pad stroke by optical scale

- Special functions: double ink I print cycles, dwell and delay before print

- European safety CE standard

- RS-232 communication system

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

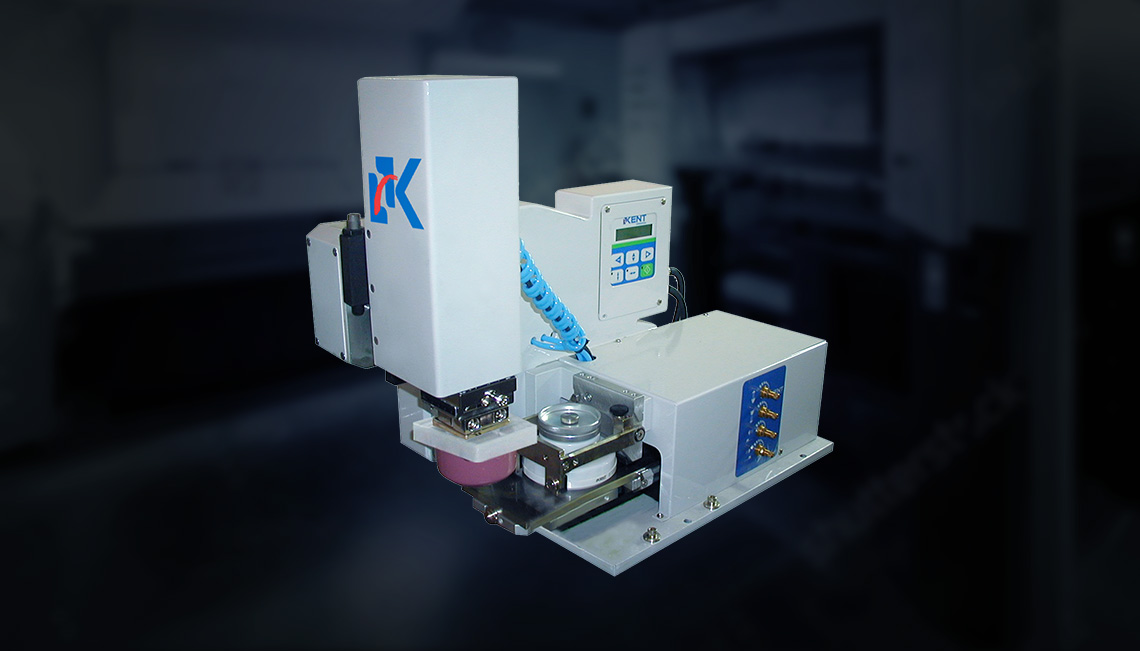

Alien 100 R - Alien High Speed Series

- High speed, single color pad-printer

- Ideal to integrate with auto-feeds, production lines or extruders

- Suitable for small batch as well as high volume printing

- Fast die plate changeover in minutes

- Extra long pad stroke, able to print below machine base

- APS: Automatic pad stroke by optical scale

- User-friendly

- Use long life Green plate, 10 mm steel plate, thin steel plate and polymer plate

- European safety CE standard

- RS-232 communication

- Light weight, rigid aluminium cast machine frame

Alien 100/2-TT - Alien High Speed Series

- Productivity is doubled with the 2-Station Turntable; print at one station - while load / unload at the other

- Automatic pad clean

- Pneumatic turntable

- Pneumatic pad stroke

- APS: Automatic pad stroke by optical scale

- THK linear guide rail with runner blocks

- KENT patented sealed ink cup system

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- RS-232 communication system

- CE European safety standard

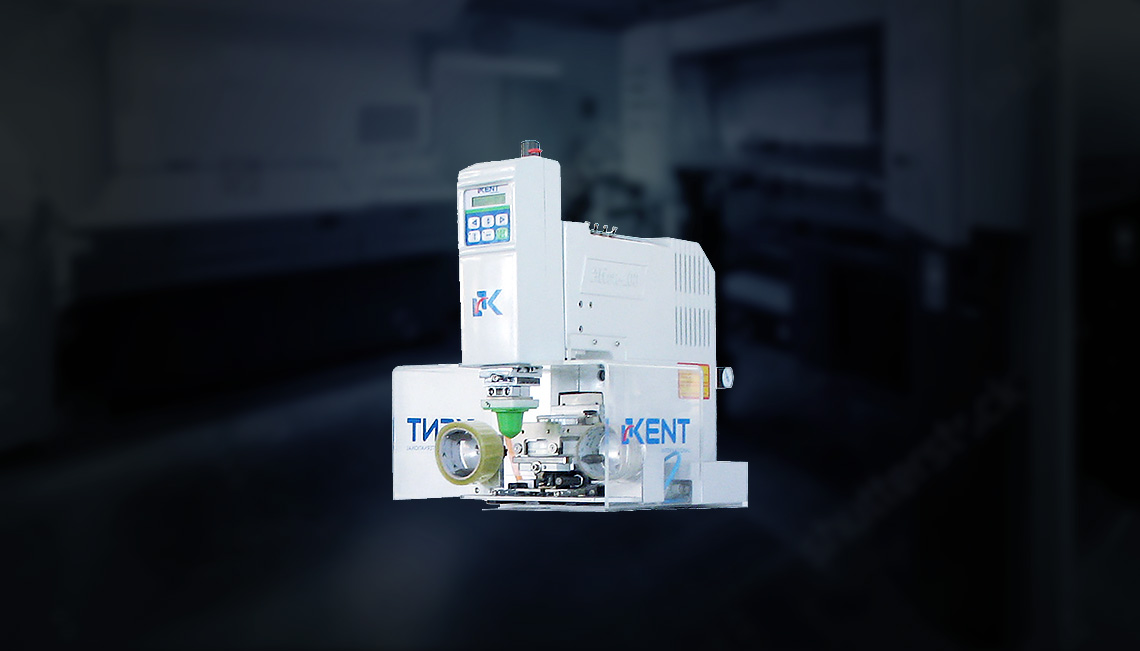

Alien 100 - Alien High Speed Series

- Rigid aluminium casting machine frame

- Pneumatic pad stroke

- Use sealed ink cup set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Fast setup, snap-on plate change

- Automatic pad cleaning with programmable cleaning cycle

- APS : Automatic pad stroke by optical scale

- Special functions: double ink I print cycles, dwell and delay before print

- European safety CE standard

- RS-232 communication system

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

KIPP200 IDS - XL Machines for Large Product/Print Requirements

- Big machine stand for steady industrial use

- Pneumatic pad carriage and up I down (Servo pad carriage optional)

- Heavy gage steel construction machine structure

- Auto pad clean (72 mm tape) (on ink cup model only)

- Use sealed ink cup or open ink tray set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Microprocessor with membrane switch control panel

- Special functions: double ink I print cycles, dwell, delay before print

- Digital pad stroke (DPS) for variable printing depth

- Safety cover

- Hardened, precision ground steel shaft with impregnated bushing ensure friction-free movement

- High speed, smooth machine movement

PP150 SCMIC - XL Machines for Large Product/Print Requirements

- For long & large image printing

- Microprocessor control, pneumatic operated pad printer

- Light weight, rigid aluminium cast machine frame

- Use sealed ink cup set up

- Compatible with long life, economy of Green plate, thin steel plate and polymer plate

- Dead-on printing plate registration for quick job change

- Membrane switch control panel

- Dwell function valve for texture surface printing

- Variable pad delay prior to printing to maximize ink transfer

- Pad stroke & speed adjustment

- Built-in pad clean platform

- Digital pad stroke (DPS) for variable printing depth

- Emergency power shut-off

- Hardened ground steel shaft with impregnated bushing ensure friction-free movement

- High speed and smooth machine operations

- CE safety standard

PP150 IDS - XL Machines for Large Product/Print Requirements

- Wide spread application on long time running mass production as well as heavy duty industrial use

- Heavy duty, rigid aluminium cast machine frame

- Use sealed ink cup system set up

- Compatible with long life, economy of Green plate, 10 mm steel plate, thin steel plate and polymer plate

- Dead-on printing plates registration for quick job change

- PLC control with touch screen interface

- Servo motor driven pad carriage (in I out)

- Pneumatic pad up I down

- Precision linear guide rail

- 700 mm wide machine stand

- Automatic pad clean with programmable cleaning cycle

- Variable pad delay, dwell function to maximize ink transfer

- Servo drive pad in/out guide rail, extended pad carriage stroke

- Special functions: double ink I print cycles, dwell and delay before print

- Digital pad stroke (DPS) for variable printing depth

- Emergency power shut-off

- Hardened ground steel shaft with impregnated bushing ensure friction free movement

- High speed and smooth machine operatoins

- Anti-dust enclosed cabinet (optional)

KCNC CNC System - CNC Pad Printing

CMIC Reconditioning Kit - Pad Printing Ancillaries

SP500 - Kent International

SP400 - Kent International

Dead-On Light Box - Pad Printing Ancillaries

Coates Pad Printing Inks

Every shade can be mixed quickly and accurately with C-Mix 2000, an ink mixing system.

Pad Printing Machinery

With a vast range of modern equipment, the latest ink and consumable technology; in house pad making, plate etching, colour matching; plus our experienced staff, Tampo will deliver the right solution for your application and budget. On the 1st of September 2015 we moved into a new facility in Sunbury on Thames.

Pad Printing Consumables

About us

Based in Sunbury on Thames, we have recently moved into a larger facility to allow for expansion of operations and improved quality service. Our focus is to offer customers a complete all round solution to their product marking and printing applications, all within their budget.

Our modern range of machines are versatile, user friendly and designed for heavy use.

We source quality equipment from world renowned suppliers Kent Engineering Co. and Coates Screen Inks GmbH.

Pad Printing Machines

- Entry Level Single & Multicolour

- Industrial Single & Multicolour

- Premium Industrial Single & Multicolour

- Inline Machines for Automated Systems

- XL Machines for Large Product/Print Requirements

- CNC Pad Printing

- Screen Printing Machines

- Ancillaries

- Coates Pad Printing Inks

- Pad Printing Additives

- Printing Pads

- Click and Fix Pads

- Printing Plates

- Pad Printing Inks

- Screen Printing Inks

- Art Development

- Colour Matched Inks

- Fixture Production

- Pad Production

- Plate Production

- Printing

- Print Sampling

- Training & Services

Images